Precision Optical Manufacturing

Manufacturing Services

At Optikos, manufacturing is more than assembly — it’s a core competency built on engineered precision, continuous improvement, and deep optical expertise. From initial prototypes and pilot runs to production volumes in the tens of thousands, our state-of-the-art facilities and experienced team help innovators bring their optical systems to market with quality, efficiency, and control.

Manufacturing Excellence

Manufacturing That Scales With You

Manufacturing needs evolve over a product’s lifecycle, from group builds and pilot runs to full production ramps. Our team is structured to support you at every phase.

Design transition

Seamlessly moving your design from model and prototype to production.

Expert guidance on development

Integrated metrology and QA

Compliance verification

Cost reduction strategies

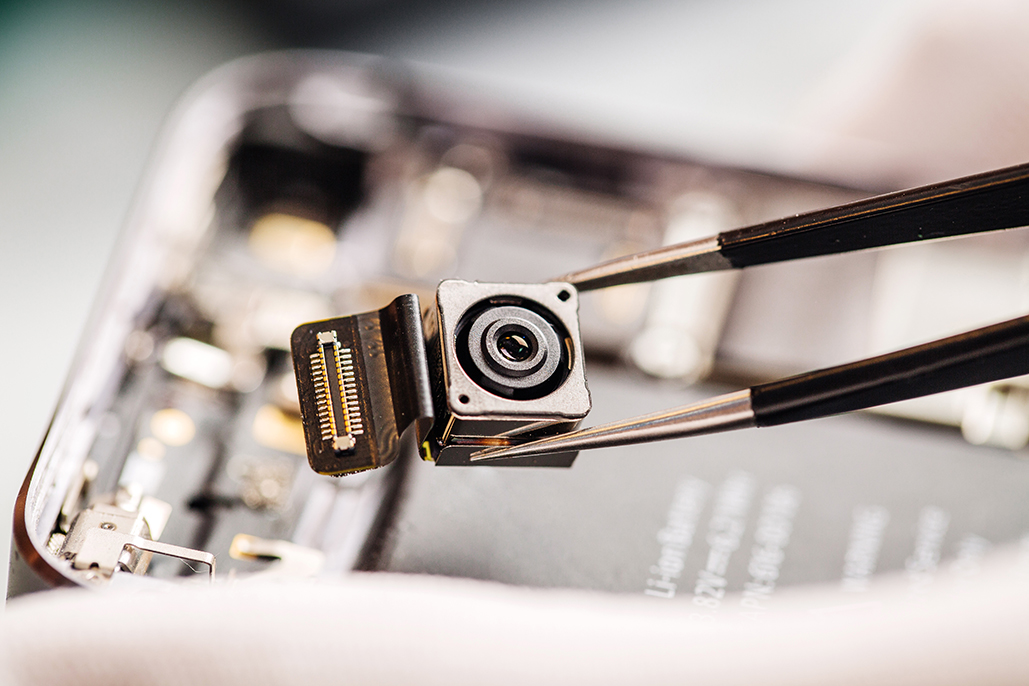

Precision Assembly

- Clean room assembly

- Automated alignment

- Quality verification

- Environmental testing

Volume scaling

- 3D printed housings

- Quick-turn fabrication

- Performance validation

- Design iteration

Manufacturing Support

- DFM optimization

- Supply chain management

- Quality systems

- Production scaling

Cost-Efficient Production

Minimizing material costs and touch time without compromising quality

Lean manufacturing

Efficient supply chain

Faster Builds

Fewer defect

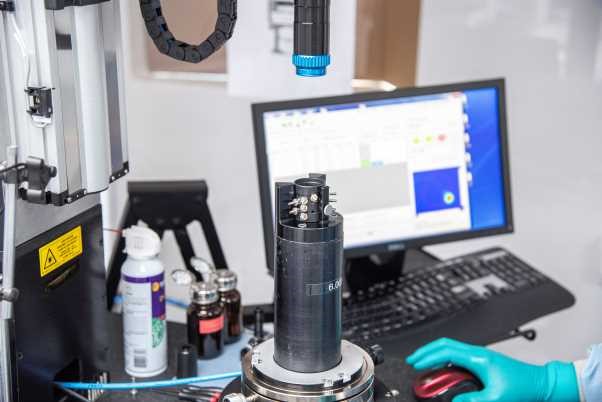

Alignment as a Service

Build lenses with very demanding performance requirements.

Control decenter and airgap

Increase throughput

Mechanical & active alignment

Visible & infrared lens assemblies

Advanced Technologies

Why You'll Like Us On Your Team

Laser Systems

Imaging Optics

Fiber Optics

Beam Shaping

Spectroscopy

Interferometry

Adaptive Optics

UV/IR Systems

Medical Devices

Defense Systems

Aerospace Optics

Industrial Automation

Key Achievements

Sub-micron precision assembly capabilities

Industry-leading alignment accuracy for critical applicationsAdvanced metrology and testing

Comprehensive validation using state-of-the-art equipmentCustom automation solutions

Proprietary assembly and testing automation systems

Industry Applications

Serving Diverse Industries Worldwide

Medical & Life Sciences

Key Achievements

- Endoscopic systems

- Laser therapy devices

- Microscopy solutions

- Diagnostic imaging

Defense & Aerospace

Key Achievements

- Targeting systems

- Surveillance optics

- Navigation instruments

- Communication links

Industrial Automation

Key Achievements

- Machine vision

- Laser processing

- Metrology systems

- Barcode scanning

Scientific Research

Key Achievements

- Spectroscopy

- Interferometry

- Particle analysis

- Beam diagnostics

Telecommunications

Key Achievements

- Fiber coupling

- Beam splitters

- Wavelength filters

- Optical amplifiers

Consumer Electronics

Key Achievements

- Camera modules

- Display optics

- Sensor systems

- Projection systems

Support Available

What We've Been Working On

Advanced Lens Alignment

Utilizing Opto Align, the premiere manufacturer of alignment tables

Electro-Optical Guidance Systems

Genomics Technology

From lab-made to manufacturing-ready.

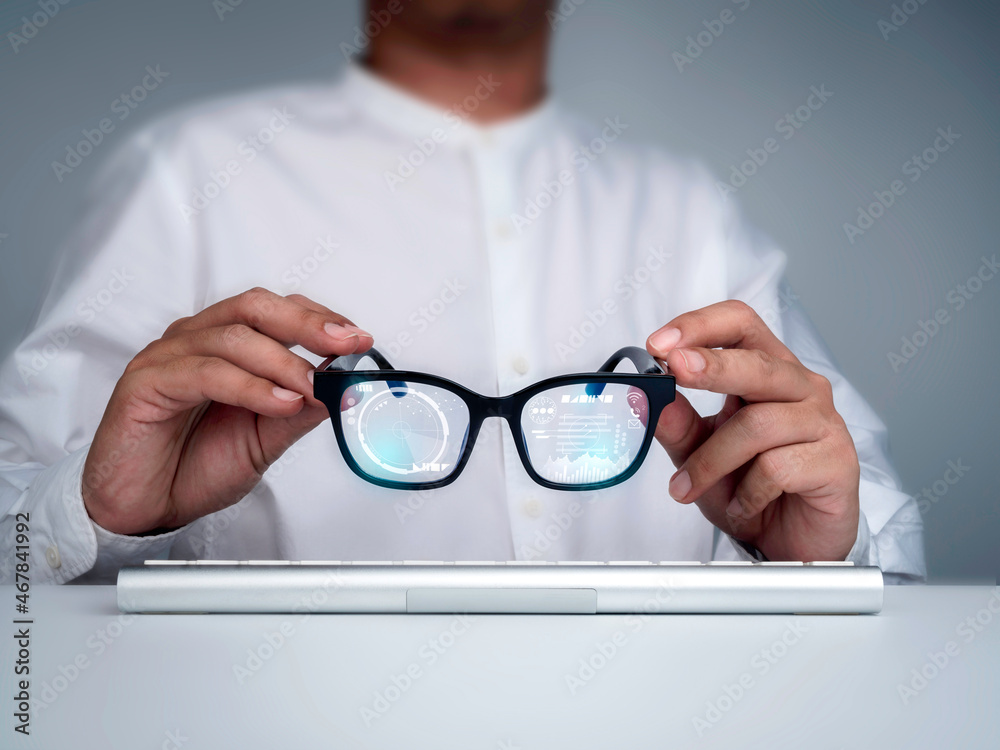

AR Display Optics

Why Choose Optikos

A Flexible Resource

Optikos provides agile and scalable manufacturing services for complex optical and opto-mechanical assemblies across industries such as medical devices, diagnostics, defense, aerospace, life sciences, and consumer imaging. With a robust engineering foundation built into every stage of production, we help you streamline build-to-print readiness, reduce manufacturing cycle times, and produce units that meet stringent performance and quality standards.

Our expanded manufacturing facility in Wakefield, Massachusetts includes dedicated cleanrooms, laminar flow stations, micron-level alignment capabilities, and integrated in-house metrology — all designed to support builds from small pilot runs to recurring production scaling into tens of thousands of units. This is supported by our modular manufacturing floor, enabling fast reconfiguration for unique build requirements.

And with integrated metrology and testing, quality is engineered into production. Our LensCheck®, OpTest®, and other metrology systems are used inline to verify performance at every critical stage, minimizing rework and maintaining consistent output that conforms to customer specifications.

Certifications & Standards

ISO 14001

ITAR

Ready to Manufacture With Confidence?

Our experts are ready to help you navigate from prototype to production excellence.