ABSTRACT

A viewfinder assembly fabricated virtually exclusively of injection molded plastics includes a housing, four lens groups, four mirrors for folding the optical path and providing for proper image orientation, and mirror retainers. All of the components are structured to snap-fit together such that the optical components of the assembly are automatically nominally positioned when placed connected in the housing. Adjustment features for lens tilt and framing are also provided and, as well, means for displaying visual information in the viewfinder field.

| Publication number | US4526444 A |

| Publication type | Grant |

| Application number | US 06/595,715 |

| Publication date | Jul 2, 1985 |

| Filing date | Apr 2, 1984 |

| Priority date | Apr 2, 1984 |

| Fee status | Paid |

| Inventors | Stephen D. Fantone, Robert M. Goward,Jonathan I. Kaplan |

| Original Assignee | Polaroid Corporation |

| Patent Citations (17), Referenced by (20), Classifications (6),Legal Events (7) | |

| External Links: USPTO, USPTO Assignment, Espacenet | |

This invention in general relates to optical devices and in particular to optical assemblies suitable for use as camera viewfinders.

2. Description of the Prior Art

Some of the most important, if not paramount, considerations for commercially successful cameras for use in amateur hand photography are cost and convenience and, as well, simplicity and reliability of operation. Also, cameras intended for use both indoors and outdoors by a relatively untrained individual desirably are lightweight and adapted for carrying or for safe storage when not in use, as on a shelf or in a drawer. These several requirements have been commonly met today by the use of molded plastics both for lenses and camera body parts because the specific gravity of plastics is low in comparison to glass and metallic materials

For cameras of the class required for instant photography, other considerations enter as the arrangement of camera loading and print ejection and a restricted range on size because of requirements related to optical path volume. More particularly, the optical path volume tends to define basic geometry around which a camera must be designed and built. That is, a camera, whether with a straight or folded optical path, will have this basic size which ultimately must expand to accommodate all of its components such as shutter, viewfinder, film transport mechanism, and so forth. For minimum size and weight then, one task is to minimize those parameters for each component required while still meeting other fundamental needs.

For instant cameras, as in others, the optical path volume, i.e., the space bounded by the extreme bundle of rays surrounding what is to be photographed, is determined by the desired angular field coverage and print diagonal dimension. Print diagonals commonly practiced range in magnitude between 3 and 5 inches, more or less, and thus required objectives have equivalent focal lengths on the order of 115 mm. Thus, one arrives at a basic volume which is approximately a truncated cone shape with a base size related to the print diagonal and an altitude of approximately 115 mm. This, of course, may be folded through the use of mirrors and film loading and ejection arrangements, but otherwise is basically fixed. Consequently, the need can be appreciated for miniaturization of all other camera components wherever possible.

Viewfinders, a necessary component for aiming the camera and giving a visual indication of what is contained in the photograph, are usually either of the single lens reflex type relying in part on the camera objective for this purpose or the independent type which functions separately from the camera objective.

The independent types today are usually for aesthetic reasons built into the camera body and employ optical systems derived more or less indirectly from a Galilean telescope. However, the reversed Galilean form of viewfinder becomes less suitable where the length of the viewfinder tends to become large as in the case of instant camera structures. Here, as the separation between divergent and convergent groups increases power adjustments force the magnification unacceptably downward. Moreover, reversed Galilean forms are afflicted with other problems such as distortion, limited field angle, field shifts and defocused field defining masks.

Other telescopic forms have been used and lengthened through the use of periscopic principles involving the use of field and relay lenses. These too suffer from narrow angular fields and are difficult to correct because of the need for extensive use of positive lenses.

It is thus a primary object of the present invention to provide a camera viewfinder.

It is another object of the present invention to provide an elongated, but otherwise minimally sized camera viewfinder.

Yet another object of the present invention is to provide a well-corrected camera viewfinder having a moderately large angular field coverage with minimum optical elements.

Still another object of the present invention is to provide a camera viewfinder which is relatively easy to fabricate, assemble, and adjust while still meeting the above-mentioned objects.

Other objects of the invention will, in part, be obvious and will, in part, appear hereinafter. The invention, accordingly, comprises the apparatus possessing the construction, combination of elements and arrangement of parts which are exemplified in the following detailed disclosure.

SUMMARY OF THE INVENTIONThis invention in general relates to optical devices and in particular to an optical assembly suitable for use as a viewfinder in a camera of moderately large picture format and requiring a relatively long, yet compact finder of normal full coverage, minimum weight, and which is easily assembled and adjusted.

Having a length approximating seven inches, an angular field coverage of 45 plastic construction, the assembly of the invention satisfies such camera requirements adequately.

The assembly itself comprises an elongated, open-ended housing having positioned therein along a folded optical axis a first lens group of negative power which is followed by four plano mirrors arranged around a second lens group and functioning to fold the optical path and provide correct image orientation.

The second group of lens elements is of positive power and operates in conjunction with the first lens group to form a real image in a predetermined plane located in the housing behind the second lens group.

At the real image plane is located an adjustable mask movable to correct for horizontal aiming.

Third and fourth positive lens groups permit the real image to be observed substantially afocally.

Retainers are provided, preferably molded of plastic along with the housing and lens components. All components to be held in place in or on the housing, and the housing itself, are provided with complementary configured snap-type connectors which allow quick assembly and automatic positioning of the lens components and all but one of the mirrors, which is adjustable in one azimuth to correct for lens tilt errors.

Means are also provided for displaying visual information in the viewfinder field.

BRIEF DESCRIPTION OF THE DRAWINGSThe novel features that are considered characteristic of the invention are set forth with particularity in the appended claims. The invention itself, however, both as to its organization and method of operation, together with other objects and advantages thereof, will be best understood from the following description of the illustrated embodiments when read in connection with the accompanying drawings wherein like numbers have been employed in the different figures to denote the same parts and wherein:

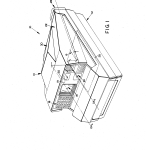

FIG. 1 is a perspective view of a folding camera which uses instant film and appears illustrated unfolded, ready for picture taking;

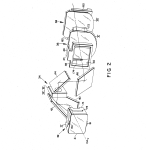

FIG. 2 is a perspective view of the optical components of the invention arranged along a folded optical axis, OA.sub.V, as a system suitable for use as part of the viewfinder for the camera of FIG. 1;

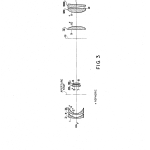

FIG. 3 is a cross-sectional view of the optical system of FIG. 2 shown unfolded and with certain parts deleted;

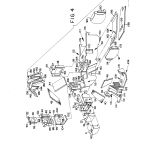

FIG. 4 is an exploded perspective view of a housing and associated retainers in which the optical components of FIG. 2 are physically connected to form a viewfinder assembly of the invention;

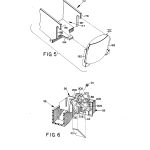

FIG. 5 is an enlarged, left rear, perspective view of a part of the housing and a lens component of FIG. 4;

FIG. 6 is an enlarged, right rear, perspective view of the forward part of the housing and a mirror of FIG. 4; and

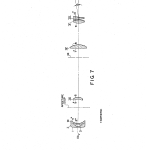

FIG. 7 is a cross-sectional view of an unfolded, alternate, optical system which may be used with the camera of FIG. 1.

DETAILED DESCRIPTIONThe present invention in general relates to optical devices and in particular to optical systems and assemblies suitable for use as viewfinders in cameras having moderately large picture formats and requiring relatively long, yet compact finders with normal angular field coverage. Thus, the present invention relates to both the optical design of a viewfinder system and to the integration of that design into a viewfinder assembly for use with a camera.

Referring now to FIG. 1, there is shown a camera 10 which is adapted in a well-known manner to accept instant or self-processable film of moderate format. The camera 10 comprises two major sections, lower body 12 and upper body 14, which are pivotally hinged about their aft ends in a well-known manner for relative rotation in clamshell-like fashion to allow the camera 10 to be folded into a compact condition (not shown) for storage and an unfolded condition in which pictures are taken. In FIG. 1, the camera 10 is as it would appear ready for taking pictures.

Upper body 14 includes a forward or scene facing, vertical wall 19 which contains a number of openings for parts or access to parts of various camera systems. Among these openings is one to the extreme left in which there is a sonar transducer 18 which forms part of an automatic rangefinding system. In the center is an opening for the camera objective taking lens 16 which is arranged along optical axis OA.sub.L. Optical axis, OA.sub.L, is folded with a mirror which resides in an internal cone-like structure (neither shown) and terminates in the center of the camera film plane shown at 28. The diagonal of the film plane is within the commonly used range of 3 to 5 inches, more or less, and the focal length of objective taking lens 16 is approximately 115 mm to provide a normal full field coverage of around 50 degrees.

To the upper right of the objective lens 16 is an opening 20 which serves as an entrance window for the camera exposure control system and directly beneath that is another opening 24 which is the entrance window to the viewfinder system of the invention.

The optical system of the invention, shown in perspective in FIG. 2 and in the exploded assembly of the invention in FIG. 4, is arranged along a multiply folded optical axis, OA.sub.L, and resides in the camera 10 in a region designated generally at 22 which is under the upper right hand corner of the upper body 14 and extends lengthwise from the vertical wall 19 aft, terminating at an eyecup 26. The last leg of the optical path, OA.sub.L, is seen offset with respect to the entrance window 24 and angled downward by an angle, θ, from the horizontal.

The overall length of the camera lower body 12 is approximately 61/2 inches and that of the upper body 14, from its vertical wall 19 to just before the eyecup 26, is about 51/4 inches, thus requiring a rather long viewfinder capable of fitting into the region 22 along with other camera system components.

As seen in FIG. 2, the optical system of the invention comprises four major lens groups, 32, 34, 36 and 38, respectively; four plano mirrors, 40, 42, 44 and 46; and an image mask 48 having an opening 50.

The power distribution among the four major lens groups, 32-38, is in form: negative, positive, positive and then positive. FIG. 3 permits the power distribution to be visualized more easily, showing the lens group individual element curvatures and spacings with the system unfolded, without the plano mirrors, 42-46, but with a prism 39 which can be part of the fourth major lens group 38. The purpose of the prism 39 is for deviating an observer’s line of sight from the horizontal into coincidence with the last leg of the optical axis, OA.sub.L. This refraction occurs when the eye looks into the camera eyecup 26 in which case the line of sight is deviated upwards by the angle, θ. With regard to mounting, the prism 39 is preferably mounted as a separate element, forward of the eyecup 26, in any well-known manner.

The first lens group 32 includes two elements, I and II, which are both negative and meniscus in form. Each rear surface of elements I and II is aspheric and both elements, I and II, are structured to be aplanatic and curved about the system aperture stop.

For reduction of vignetting and minimization of the size of elements III and IV, which comprise the second lens group 34, the aperture stop is preferably made close to surface 5 of element II, but can move forward of this location, but by no more than one-third the distance separating groups 32 and 34.

Elements I and II are generally structured in the foregoing manner to operate to form a virtual image of the photographic scene which is then imaged by the second positive lens group 34 as a real image at the location of the mask 48 and at the dimensions of the mask aperture 50.

Element III is meniscus with its rear surface 6 aspheric and element IV is of plano-convexo form, both operating to provide the second lens group 34 with overall positive power.

The real image formed by the first and second lens groups, 32 and 34, is observable via the third and fourth lens groups, 36 and 38, which taken together are focused on the mask aperture 50. These two groups are structured to operate to form a substantially collimated or slightly converging image of the photographic scene, making the optical system overall afocal or nearly so.

Constructional data for a preferred example in quantitative detail is given in the following table with reference to FIG. 3.

______________________________________Ele- Sur- Separationment face Radius Medium Air N.sub.d V.sub.d______________________________________I 1 3.5959 .0854 1.4917 57.2 2* .5463 .2136II 3 1.2433 .0854 1.4917 57.2 4* .7212 2.0962III 5* -3.2708 .0854 1.4917 57.26 -2.1673 .0142IV 7 -891.8444 .0854 1.4917 57.28 -.9827 4.3788V 9 plano .2534 1.4917 57.210* -2.079 1.237VI 11* 1.6637 .3080 1.4917 57.212 -4.5623______________________________________ *aspheric

in which said surfaces are numbered in their order from object to image space, said radii and separations are normalized with respect to the combined focal length, f.sub.o, of said first through said fourth element, N.sub.d is the index of refraction, V.sub.d is the Abbe dispersion number and wherein surfaces 2, 4, 5, 10 and 11 are aspheric in shape and have the general formula: ##EQU1## where C is the reciprocal of the surface apex radius, Z represents the distance of a point on the aspheric surface measured from the surface vertex and parallel to the Z-axis taken to be the optical axis, S is the radial distance of the point measured perpendicular to the Z-axis and wherein the coefficients, β through ε, and the conic constant K, normalized to f.sub.o are:

______________________________________Surface2 4 5 10 11______________________________________K -2.0596 0.0 0.0 0.0beta 0.0 1.3122 -1.6966 0.0 -4.3989 10.sup.-1 10.sup.-2gam- 0.0 0.0 -3.3069 0.0 -3.0754 ma 10.sup.-2 10.sup.-3delta0.0 0.0 0.0 0.0 0.0epsi-0.0 0.0 0.0 -9.3215 0.0lon 10.sup.-2______________________________________

The material for all elements of this example is preferably plexiglass, but can be any low dispersion optical material of suitable index. The two front lens groups and the two back are for reasons to follow of themselves corrected for distortion. Mirrors 40-46 operate to fold the optical axis, OA.sub.L, four times to promote compactness and provide for proper image orientation.

The optical system parts are adapted in a manner to be described to fit together with other components to form the viewfinder assembly as best seen in FIGS. 4, 5 and 6.

The general characteristics of the viewfinder assembly are that it is fabricated virtually exclusively of injection molded plastics and includes a housing, the optical system four lens groups and mirrors, and mirror retainers. All of its components are structured to snap-fit together such that the optical components of the assembly are automatically nominally positioned when connected in the housing. Adjustment features for lens tilt and horizontal framing are also provided and, as well, means for displaying visual information in the viewing field.

Specifically, the assembly comprises an elongated housing 52 having open ends 64 and 177 fore and aft, respectively. The housing 52 is injection molded of a suitable glass filled thermoplastic such as 30% filled polycarbonate for dimensional stability and includes three major sections, a forward section 54 which faces the scene, a prismatic midsection 56 for receiving the optical system mirrors, 40-46 and the second lens group 34, and an aft section 58 which extends rearwardly and downwardly along the angle, θ and is adapted to receive the optical system third and fourth lens groups, 36 and 38, respectively, and visual indicating means to be identified.

Forward housing section 54 includes a forward rectangular section 60 and a rearward one 62 which is dimensioned to fit into the forward one 60 to form a seating surface, partially shown at 61, where these two sections interface.

The lens element II is provided with four bosses 74 which project rearwardly from its four corners and seat on the surface 61, and lens element I also has four rearwardly projecting bosses 78 which seat in complementary configured surfaces 76 on lens element II.

Both lens elements I and II are retained in the forward housing section 54 with a snap-fit retainer arrangement. At the top and bottom of the section 60 are flexible cantilevered fingers 66 and 68, respectively, each of which is provided with a hole, 70 and 72 respectively, and are otherwise adapted to deflect outwardly in the presence of lateral loads.

Lens element I includes two wedge sections, 80 and 81, located in its top and bottom respectively, (see FIG. 2), which cam the flexible fingers, 66 and 68, apart as the lens elements I and II are inserted into section 60 and then drop into the holes 70 and 72 to retain the lens elements, I and II, in place. The deflection of these flexible fingers, 66 and 68, is made, along with all other snap-fit assembly features to be described, so as not to be overstressed during assembly. This assures elastic performance and ease of disassembly if required.

Mid housing section 56 as best seen in FIGS. 4 and 6 is adapted to receive and retain therein the four mirrors, 40-46, and the lens elements III and IV of the second lens group 34 as a drop-in subassembly.

The optical surfaces of lens elements III and IV are formed as an integral part of two separate parts, 82 and 90, respectively, adapted to fit together in complementary fashion. The active optical areas are designated at 86 and 92, respectively, and it is these areas which are in the forms of the refracting surfaces of these elements as shown in FIG. 3 and as described previously.

Part 82 is formed with a recess 84 in which there is a U-shaped section 87 that defines in conjunction with the rear surface of part 82 a second recess 88 that is depressed below the rear surface of part 82.

Part 90 fits into the recess 88 and is positioned vertically with a tee member 94, the ends of which bear against seating areas 93 (only one shown) at the top of section 87 of part 82.

Both parts, 82 and 90, fit into a spring retainer 96 which includes a vertical front wall 97 having a clear aperture 98, a horizontal base wall 102, and a vertical side wall 100. Front wall 97 and side wall 100 have flexible fingers shown typically at 104.

Now, in the housing 56 there is a vertically facing channel formed between four upstanding posts 124, 126, 200 and 202 (FIG. 6). The drop-in subassembly slides into this channel and is loaded by the spring fingers 104 so that it is positioned laterally of the optical axis, OA.sub.L, and the rear surface of part 82 seats against the forward facing surfaces of the posts 126 and 200 to position this subassembly axially.

Mirrors 42 and 44 drop into the top of housing section 56 and seat on three point mounts which orient them in planes of 45 degrees. As seen in FIG. 4, the mirror 44, which is rectangular, mounts on two upper posts 128 (one shown) adjacent posts 126 and 200 and on a boss 130.

Mirror 42, which is trapezoidal, mounts also in a plane, which is also defined by a three point mount. As best seen in FIG. 6, this mount includes surfaces 203 (one shown) adjacent posts 202 and 124 and boss 204.

Mirrors 42 and 44 are retained against their mounting planes by an upper mirror retainer 138 shown best in FIG. 4. The retainer 138, a glass filled injection molded piece, includes a top piece 139 having depending therefrom slanted side pieces 140 and 142 and flexible fingers 144 (one shown) which extend downwardly and are provided with apertures 146.

In side piece 140 are flexible fingers 150, 151 and 156 corresponding to the three points for defining the mounting plane for mirror 44 and in top piece 139 is a flexible finger 139 corresponding to the top mid point of the tee 94 of part 90. Side piece 142 is also provided with flexible fingers in the above manner and partially seen for the three point mount for mirror 42.

On either side of section 56 are wedges 132 (one only shown) which separate the flexible fingers 144 and fit into their holes 146 as decribed before to connect the mirror retainer 139 to housing section 56 thereby keeping the mirrors 42 and 44, firmly in place against their three point mounting planes.

In FIG. 6 there is seen provided in housing section 56 an aperture 206 over which the mirror 42 resides when in place, and this aperture 206 serves as the aperture stop for the optical system as previously described and seen in FIG. 3.

A lower mirror retainer 106 is provided as an injection molded part for retaining the mirrors 40 and 46 in place. Although somewhat different in geometry than the retainer 139, the retainer 106 is similar to it in principle of operation. As seen in FIG. 4, retainer 106 has two major sections, 108 and 110. Section 108 is for mirror 46 which mounts facing rearwardly and downwardly from 45 degrees to provide the angle, 0, and section 110 is for mirror 40 which faces forwardly and is adjustable in a manner to be described for accommodating for any tilt errors of the lens elements in the first and second lens groups, 32 and 34.

Retainer 106 snaps onto the housing 52 via flexible fingers 116 and 118 located respectively on sections 110 and 108. Flexible finger 118 fits into an aperture 136 located in the vertical right side wall of rear housing section 58 and finger 116 snaps around wedges 212 pictured in FIG. 6.

Mirror 46 seats on a three point mounting plane of the sort previously described, but not now shown, and mirror 40 seats on a three point mounting plane in which one point is moveable to provide tilt adjustment. The bosses 114 located on a flexible finger 112, formed as part of the lower retainer section 110, bear against two of the points located in the section 56, and the third point, which is adjustable, is provided in the form of an adjustment screw 211 which fits into threaded hole 210 (FIG. 6) or other suitable means.

Lens V snaps into the rear housing section 58 from its underside and for this purpose is provided on either side with a pair of wedge-shaped ears 172 and 174 which cam apart the side walls of the rear housing section 56 and fit into a pair of vertical slots 170 (only one shown) dimensioned to receive them.

Lens VI, shown in FIG. 5, fits into the open end 177 of rear housing section 58 through the use of side posts 180 and 182 along with corresponding hook sections 176 and 178, respectively, and a flexible finger 184. Here, the upper surfaces of the side posts 180 and 182 are rounded to fit the inner surfaces of the hooks 176 and 178 which then act as bearing surfaces about which the lens element VI is rotated until its lower edges are captured by the flexible finger 184. This completed, the forward facing surfaces of the side posts 180 and 182 are seated against respective rearward facing surfaces 185 and 187 of the ends of the housing section 58. With this arrangement, lens VI is securely positioned in place.

Mask 48 is placed in the rear housing section 58 in the following way. As seen in FIG. 4, the rear housing section 58 includes, across its top opening, a cross-member 160 which has provided in it a pair of slots 162 and 164 which intersect one another in a common space inside of cross-member 160. Mask 48 has a rearward projection 47 which fits into slot 162 and flexes a portion 161 of cross-member 160 vertically via a wedge sction 49 which then projects through slot 164. Since the width of section 47 is narrower than that of the slots 162 and 164, the mask 48 is free to slide horizontally, thereby making it adjustable in this direction. After being adjusted properly so that the viewfinder horizontal field is correct, the mask 48 with this arrangement is automatically fixed in place.

Means for displaying visual information are provided in the form of a circuit board 198 having integrated therewith light emitting diodes 199 or the like coded to provide the camera user with indications of the state of various camera functions or scene characteristics. The circuit board mounts with a mounting board 184 with the diodes 199 registered in optical communication with a prism 190 located atop the board 184. These two components may be joined in any well-known manner. The board 184 has a pair of upwardly depending elongated end sections 186 and 188 which slide into complementary configured slots 192 and 194 provided in the rear housing section 58 for this purpose. Note also the presence in rear housing section 58 of a wedge shaped cutout 196 which provides clearance for the prism 190.

When the board 184 is in place in the rear housing secton 58, the prism 190 is in position with its rearwardly facing surface in the plane of the real image formed by the first and second lens groups, 32 and 34, and is arranged to direct light from the diodes 199 into the third lens group 36 where this light can then be seen by an observer in the field of the optical system without distortion since the third and fourth lens groups, 36 and 38, are corrected together to be distortion-free, primarily by the strong higher order aspheric terms of surface 10, and are focused also on this real image plane.

An alternate optical system design in accordance with the principles of the invention is shown in cross-section unfolded fashion and without any mirrors in FIG. 7. This alternate has the following constructional data:

______________________________________Alternate Optical System ExampleEle- Sur- Separationment face Radius Medium Air N.sub.d V.sub.d______________________________________I 1 3.2650 .0608 1.4917 59.2 2* 0.4697 .1825II 3 1.1289 .0608 1.4917 59.2 4* 0.6263 1.7779III 5* -2.7873 .1216 1.4917 59.2 6 -0.6143 3.8863IV 7* plano .2311 1.4917 59.2 8 -1.5206 1.6469V 9 1.2165 .1825 1.4917 59.2 10* -9.1068______________________________________ *aspheric

in which said surfaces are numbered in their order from object to image space, said radii and separations are normalized with respect to the combined focal length, f.sub.o, of said first through said third element, N.sub.d is the index of refraction, V.sub.d is the Abbe dispersion number and wherein surfaces 2, 4, 5, 7 and 10 are aspheric in shape and have the general formula: ##EQU2## where C is the reciprocal of the surface apex radius, Z represents the distance of a point on the aspheric surface measured from the surface vertex and parallel to the Z-axis taken as the optical axis, S is the radial distance of the point measured perpendicular to the Z-axis and wherein three coefficients, β through ε, and the conic constant K, normalized to f.sub.o are:

______________________________________Surface2 4 5 7 10______________________________________K -2.3073 0.0 -4.2598 0.0 0.0 10.sup.-1beta 0.0 1.8387 -5.4764 -3.9491 9.0058 10.sup.-1 10.sup.-2 10.sup.-2gam- 0.0 0.0 -1.4393 9.7311 -5.4472 ma 10.sup.-1 10.sup.-3 10.sup.-2delta0.0 0.0 9.8715 0.0 0.0 10.sup.-1epsi-0.0 0.0 0.0 0.0 0.0lon______________________________________

From FIG. 7 and the tabular constructional data, it can be seen that the alternate optical system has one less element in its second lens group and the element used, element III here, is positive and of meniscus form. The other elements are in form similar to the first example and again all are made of optical quality plexiglass.

Obviously, the foregoing examples may be rescaled, and in this process it is required to determine numerical values to go with the rescaling for the new physical size.

It will be obvious to those skilled in the art that other changes may be made in the above-described embodiments without departing from the scope of the invention. Therefore, it is intended that all matter contained in the above description or shown in the accompanying drawings shall be interpreted as illustrative and not in a limiting sense.

CLAIMS(15)

What is claimed is:

1. A viewfinder assembly for use with a photographic camera, said assembly comprising:

an elongated, open-ended housing;

a first lens group consisting of at least one element of negative power positioned in said housing;

a second lens group consisting of at least one element of positive power positioned in said housing, the powers of said first and second lens groups, and the spacing therebetween being such that said lens groups in combination are convergent, forming a real image in a predetermined plane within said housing located behind said second lens group;

a third lens group consisting of at least one element of positive power positioned in said housing; and

a fourth lens group consisting of at least one element of positive power positioned in said housing, the powers of said third and fourth lens groups and the spacing therebetween being such that said third and fourth lens groups form a substantially collimated image of said real image formed by said first and second lens groups,

said housing having positioned therein and said lens groups having positioned thereon complementary configured snap-type connecting means structured to automatically connect said lens groups in said housing so that said lens groups are automatically arranged with respect to one another along an optical path within predetermined tolerances upon connection with said housing.

2. The assembly of claim 1 wherein said optical path of said viewfinder assembly is folded.

3. The assembly of claim 2 wherein said optical path of said viewfinder assembly is folded four times.

4. The assembly of claim 3 wherein said viewfinder assembly further includes four plano mirrors, one for each of said folds in said optical path.

5. The assembly of claim 1 further including a plurality of plano mirrors for folding said optical axis a corresponding number of times and wherein said housing is further structured to have mounted therein on fixed planes all except one of said mirrors and includes means for mounting said remaining mirror in a plane adjustable in one azimuth for correcting lens tilt errors in said azimuth.

6. The assembly of claim 5 further including mirror retaining means for keeping said plano mirrors continuously biased against their respective mount planes wherein said mirror retaining means and said housing each have positioned thereon complementary configured snap-type connectors for automatically connecting one to the other.

7. The assembly of claim 5 wherein said plurality of mirrors are four in number.

8. The assembly of claim 5 further including means for adjusting the framing of said viewfinder assembly in an azimuth perpendicular to said azimuth in which said mirror is adjustable.

9. The assembly of claim 5 wherein said housing comprises three major sections including a first section to be aimed into object space, a second section of generally prismatic shape arranged at right angles with respect to said first section, and a third section, larger than said first two sections, connected with said second section and having its major axis offset and skewed with respect to the path along which light travels in entering said first section.

10. The assembly of claim 9 wherein said first lens group mounts in said first section, said second lens group in said second section, said third and fourth lens groups in said third section, and all of said mirrors in said second section.

11. The assembly of claim 10 wherein said first lens group comprises two lens elements and wherein said first housing section and said first lens group elements are configured and arranged with respect to one another so that said first group lens elements mount in said first section, one on top of the other, for automatic spacing therebetween along said optical axis, and insert into said first section in a direction generally parallel with said optical axis.

12. The assembly of claim 10 wherein said second, third and fourth lens groups mount into said housing in a direction generally perpendicular to said optical axis.

13. The assembly of claim 1 further including means for displaying information visible within the field of said viewfinder assembly.

14. The assembly of claim 13 wherein said second and third lens groups are jointly well-corrected for distortion and wherein said information is displayed at or nearly at the apparent location of said real image.

15. The assembly of claim 14 wherein said displaying means includes prism means.

| Cited Patent | Filing date | Publication date | Applicant | Title | |

|---|---|---|---|---|---|

| US2800052 * | Jul 12, 1955 | Jul 23, 1957 | Ednalite Optical Company Inc | Combination wide angle and telephoto lens attachment | |

| US3379092 * | Jul 5, 1963 | Apr 23, 1968 | Voigtlaender Ag | Albada type viewfinder with reduction of interference due to reflected light rays | |

| US3575082 * | Jun 24, 1968 | Apr 13, 1971 | Eastman Kodak Co | Albada viewfinder having three lens components | |

| US3661065 * | Feb 6, 1969 | May 9, 1972 | Furuta Mitsuo | Device for optical focusing a glass fiber plate as a focusing screen | |

| US3800309 * | Oct 2, 1972 | Mar 26, 1974 | Polaroid Corp | Exposure, viewing and focusing system | |

| US4097881 * | Jul 30, 1976 | Jun 27, 1978 | Sankyo Kogaku Kogyo Kabushiki Kaisha | Focussing apparatus for cameras | |

| US4104663 * | Apr 25, 1977 | Aug 1, 1978 | Minolta Camera Kabushiki Kaisha | Multiple objective lens camera | |

| US4124858 * | May 25, 1977 | Nov 7, 1978 | Polaroid Corporation | Photographic camera having independent viewfinder and reflex focusing system | |

| US4339188 * | Mar 23, 1981 | Jul 13, 1982 | Beattie Systems, Inc. | Bright screen optical viewer apparatus and method | |

| US4348090 * | May 22, 1981 | Sep 7, 1982 | Nippon Kogaku K.K. | Inverted Galilean finder | |

| US4392732 * | Dec 28, 1981 | Jul 12, 1983 | Polaroid Corporation | Folding camera with viewfinder having independently mounted optical elements | |

| DE883664C * | Apr 5, 1942 | Jul 20, 1953 | Optische Werke Steinheil Gmbh | Optisches System fuer Periskope | |

| * | DE890722C | Title not available | |||

| DE1098232B * | Mar 19, 1959 | Jan 26, 1961 | Leitz Ernst Gmbh | Sichtgeraet fuer Fahrzeuge u. dgl. | |

| GB132303A * | Title not available | ||||

| IT422907A * | Title not available | ||||

| IT535474A * | Title not available |

| Citing Patent | Filing date | Publication date | Applicant | Title |

|---|---|---|---|---|

| US4653884 * | Mar 31, 1986 | Mar 31, 1987 | Polaroid Corporation | Foldable camera accessory for photographing electro-luminescent images |

| US4673262 * | Dec 4, 1984 | Jun 16, 1987 | Canon Kabushiki Kaisha | Compact finder |

| US4701039 * | Nov 1, 1985 | Oct 20, 1987 | Polaroid Corporation | Copy accessory for instant camera |

| US4754296 * | Nov 21, 1985 | Jun 28, 1988 | Polaroid Corporation | Method of and apparatus for displaying alphanumeric range in camera viewfinder |

| US4969723 * | Dec 9, 1988 | Nov 13, 1990 | Canon Kabushiki Kaisha | Parallax adjusting mechanism for a finder device |

| US4992809 * | Oct 26, 1989 | Feb 12, 1991 | Asahi Kogaku Kogyo Kabushiki Kaisha | Zoom finder system |

| US5193030 * | Oct 11, 1990 | Mar 9, 1993 | Asahi Kogaku Kogyo K.K. | Zoom finder system |

| US5225927 * | Apr 27, 1990 | Jul 6, 1993 | Asahi Kogaku Kogyo K.K. | Real image type finder having cemented lens with at least one resin lens element |

| US5376984 * | Oct 15, 1992 | Dec 27, 1994 | Asahi Kogaku Kogyo Kabushiki Kaisha | Real image type finder |

| US5548366 * | Jul 21, 1995 | Aug 20, 1996 | Nikon Corporation | Camera viewfinder with uniform component positioning regardless of angle of view of attached lens |

| US5589991 * | Nov 19, 1993 | Dec 31, 1996 | Plx Inc. | Optical assembly with folding mirror assembly |

| US5633753 * | Oct 11, 1994 | May 27, 1997 | Mobi Corporation | Low-cost, light-weight, compact binoculars |

| US5646777 * | Oct 26, 1994 | Jul 8, 1997 | Nikon Corporation | Keplerian zoom finder optical system |

| US6031662 * | Feb 6, 1998 | Feb 29, 2000 | Fisher – Price, Inc. | Convertible binocular/stereoscope device |

| US6433943 | Nov 14, 2000 | Aug 13, 2002 | Mobi Corporation | Method for manufacturing roof mirrors |

| US6439171 | May 15, 2001 | Aug 27, 2002 | Rheem Manufacturing Company | Inner door/burner assembly for fuel-fired water heater |

| US6547558 | Mar 4, 2002 | Apr 15, 2003 | The Water Heater Industry Joint Research And Development Consortium | Methods of making a fuel-fired heating appliance |

| US6554610 | Mar 4, 2002 | Apr 29, 2003 | The Water Heater Industry Joint Research And Development Consortium | Methods for constructing a combustion chamber access door and associated apparatus |

| USRE35600 * | Feb 10, 1995 | Sep 2, 1997 | Asahi Kogaku Kogyo Kabushiki Kaisha | Zoom finder system |

| EP0588278A2 * | Sep 13, 1993 | Mar 23, 1994 | Eastman Kodak Company | One piece viewfinder and fabrication process |

| U.S. Classification | 359/362, 396/386, 359/819 |

| International Classification | G03B13/06 |

| Cooperative Classification | G03B13/06 |

| European Classification | G03B13/06 |

| Date | Code | Event | Description |

|---|---|---|---|

| Jun 8, 2005 | AS | Assignment |

Owner name: POLAROID CORPORATION (F/K/A OEP IMAGING OPERATING

Free format text: U.S. BANKRUPTCY COURT DISTRICT OF DELAWARE ORDER AUTHORIZING RELEASE OF ALL LIENS;ASSIGNOR:JPMORGANCHASE BANK, N.A. (F/K/A MORGAN GUARANTY TRUST COMPANY OF NEW YORK);REEL/FRAME:016621/0377

Effective date: 20020418

|

| Apr 9, 2001 | AS | Assignment |

Owner name: MORGAN GUARANTY TRUST COMPANY OF NEW YORK, NEW YOR

Free format text: SECURITY AGREEMENT;ASSIGNOR:POLAROID CORPORATION;REEL/FRAME:011658/0699

Effective date: 20010321

Owner name: MORGAN GUARANTY TRUST COMPANY OF NEW YORK 60 WALL

|

| Dec 23, 1996 | FPAY | Fee payment |

Year of fee payment: 12

|

| Dec 21, 1992 | FPAY | Fee payment |

Year of fee payment: 8

|

| Dec 9, 1988 | FPAY | Fee payment |

Year of fee payment: 4

|

| Apr 2, 1984 | AS02 | Assignment of assignor’s interest |

Owner name: FANTONE, STEPHEN D.

Effective date: 19840330

Owner name: GOWARD, ROBERT M.

Effective date: 19840328

Owner name: KAPLAN, JONATHAN I.

Owner name: POLAROID CORPORATION 549 TECHNOLOGY SQ CAMBRIDGE M

|

| Apr 2, 1984 | AS | Assignment |

Owner name: POLAROID CORPORATION 549 TECHNOLOGY SQ CAMBRIDGE M

Free format text: ASSIGNMENT OF ASSIGNORS INTEREST.;ASSIGNORS:FANTONE, STEPHEN D.;GOWARD, ROBERT M.;KAPLAN, JONATHAN I.;REEL/FRAME:004245/0858;SIGNING DATES FROM 19840328 TO 19840330

|