Contract Manufacturing

At Optikos, Contract Manufacturing is a Core Competency

Contract Manufacturing

At Optikos, Contract Manufacturing is a Core Competency

Product development from design through contract manufacturing

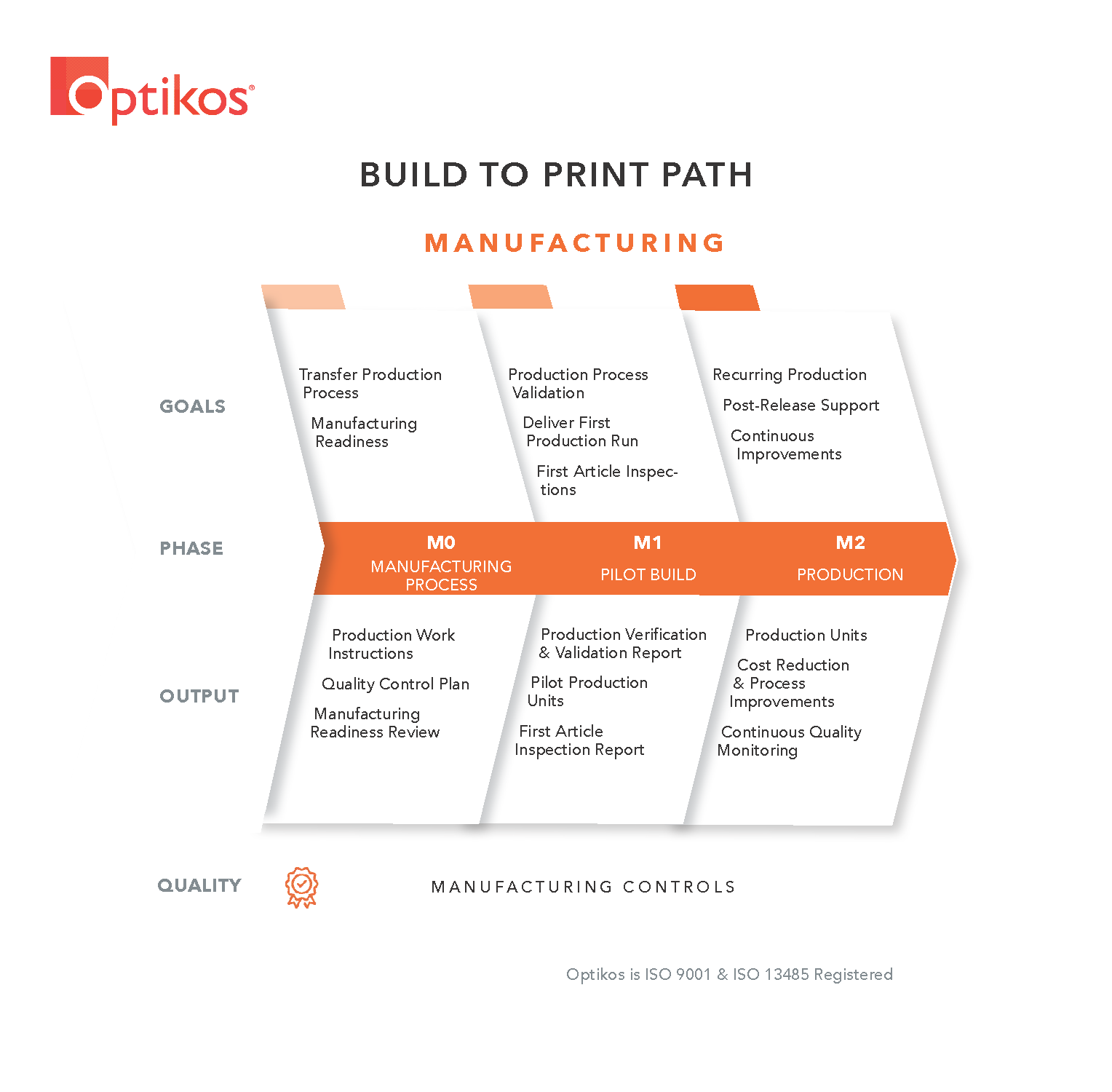

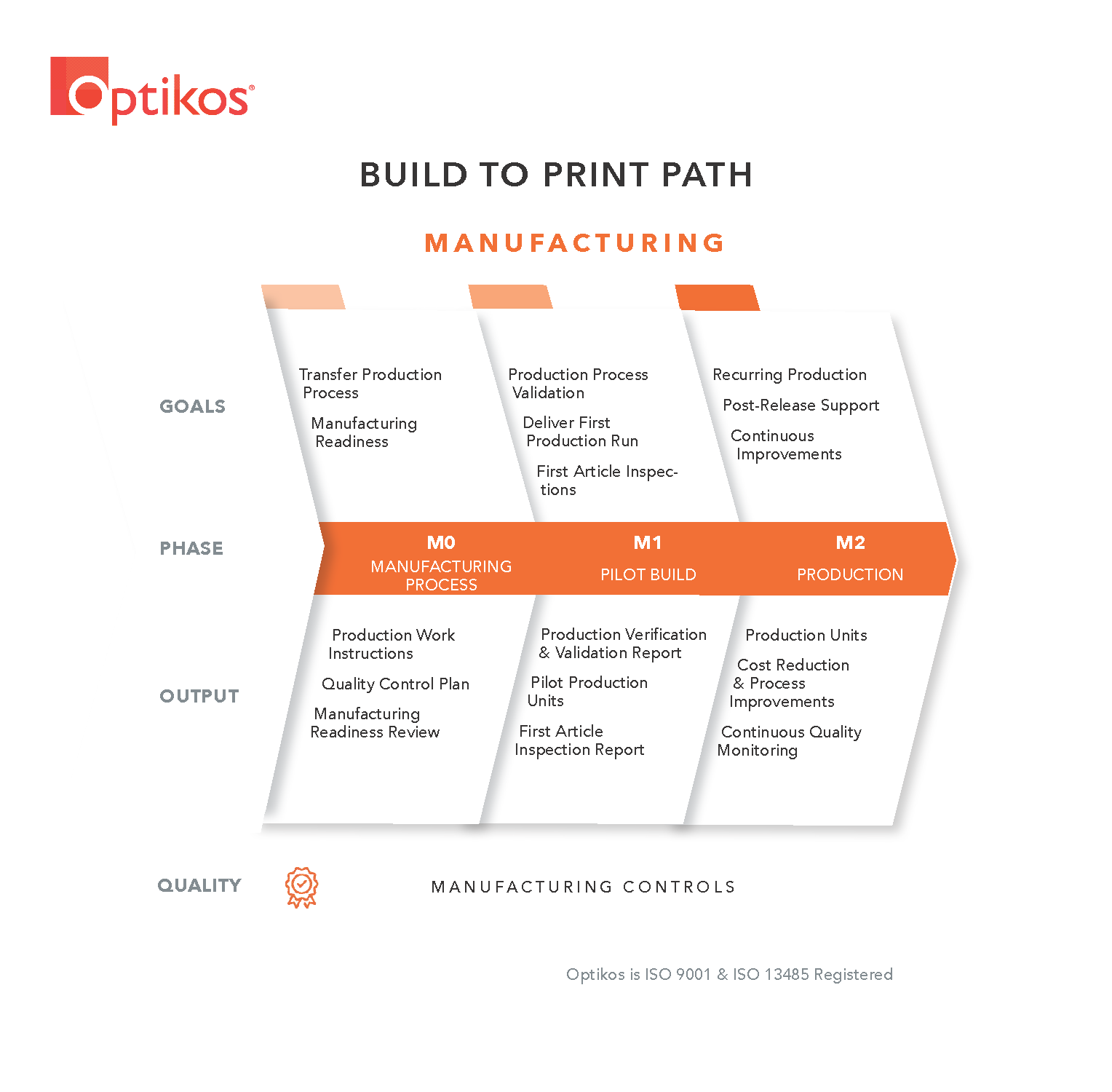

Optikos provides contract manufacturing services to a diverse client base ranging from providers of aerial imaging services to manufacturers of medical devices and diagnostic instrumentation. Clients often come to Optikos for expert design and development services and continue to work with us from prototype to full-scale production to accelerate their speed to market and ensure a quality outcome.

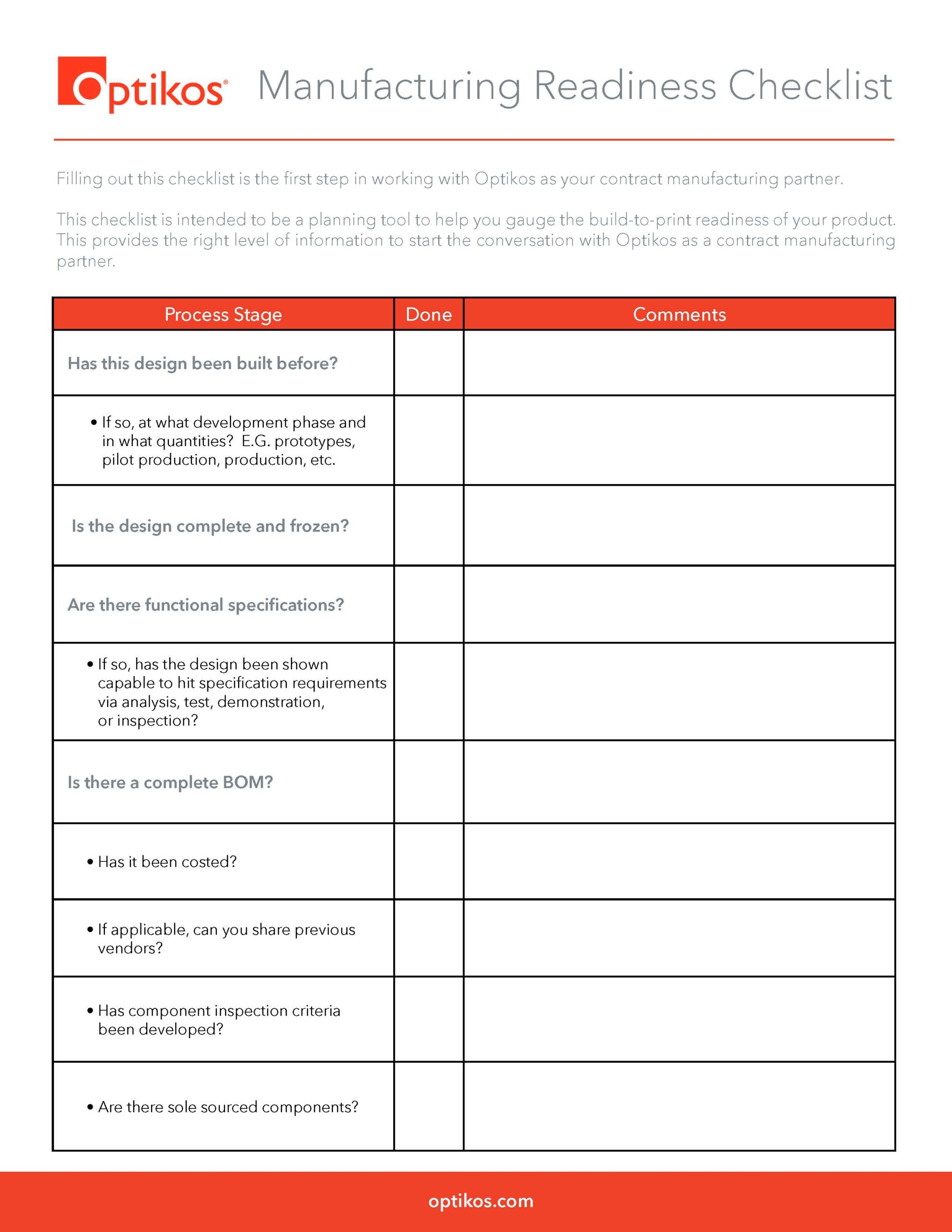

This checklist is intended to be a planning tool to help you gauge the build-to-print readiness of your product. This provides the right level of information to start the conversation with Optikos as a contract manufacturing partner.

This checklist is intended to be a planning tool to help you gauge the build-to-print readiness of your product. This provides the right level of information to start the conversation with Optikos as a contract manufacturing partner.

Expanded manufacturing capability

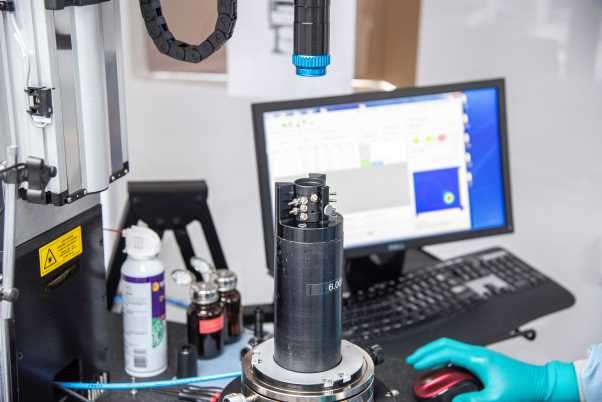

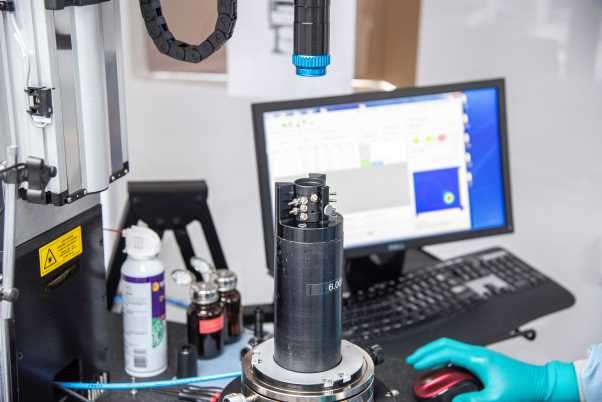

Our manufacturing facility—recently expanded by an additional 11,000 sq. ft.—is located at our headquarters in Wakefield, Massachusetts. The facility includes dedicated cleanrooms and laminar flow workstations, comprehensive metrology and testing laboratories, and work is overseen by the Optikos Engineering Services team—ensuring continuity from design to manufacturing at scale.

Broadly skilled, expert engineering team

Projects are led by a highly skilled group of optical, opto-mechanical, electrical, and software engineers and technicians. Our engineers can quickly resolve any issues faced during the scale-up to mass production of any optical system, saving substantial time and engineering resources for our customers.

Optikos has nearly 40 years of experience in developing state-of-the-art optical systems that range from consumer products to high-end military imaging systems, incorporating the latest design approaches and component materials and fabrication technologies. Where appropriate, Optikos utilizes aspheric and free-form optics as well as conventional and unconventional materials to develop systems that literally span the optical spectrum. We consider the appropriate assembly processes during the design phase so that we can be assured the product is ready to manufacture, and use the latest assembly methods when needed—including active centering and adjustable compensation. These capabilities, when paired with our optical metrology labs, measure and assure image quality early in the process—and make Optikos the ideal partner to support your production activities.

Certified to ISO 9001:2015 and 13485:2016

You can depend on the quality of our process, products, and services–Optikos is certified to ISO 9001:2015 and ISO 13485:2016 standards–and we incorporate design for manufacturing, lean concepts, detailed work instructions and global supply chain management to allow us to streamline, enhance and support your project’s development.

Alignment Turning Capabilities

Alignment Turning combines an optical alignment telescope with an ultra-precision turning center. By combing optical feedback with an automated machining process, we can control decenter and airgap to micron level precision.

Alignment Turning enables Optikos to build ultra-high precision lens assemblies in a cost-effective, high throughput manufacturing setting. Optikos has found that Alignment Turning can reduce lens assembly touch time by 5x or more, while also yielding improved performance.

When combined with world-class optical and opto-mechanical design skills, and world class metrology, there is almost no problem Optikos can’t solve

A Flexible Resource

You can work with Optikos at any point in your product development process, whether you need one specific service or a one-stop-shop. We offer a flexible, scalable resource that helps you fill a competency gap when you need it, so you can focus on the business you’re in.

A Flexible Resource

You can work with Optikos at any point in your product development process, whether you need one specific service or a one-stop-shop. We offer a flexible, scalable resource that helps you fill a competency gap when you need it, so you can focus on the business you’re in.

Hear It from the Optical Engineering Experts®

Expert-written blogs from our on-site engineering staff.

Hear It from the Optical Engineering Experts®

Expert-written blogs from our on-site engineering staff.

Lens Alignment as a Service at Optikos

What is active lens alignment? Active alignment is a process in which lenses are individually manipulated to bring them into alignment with a defined axis. Generally, this axis is based off of mechanical datums of a lens barrel. Each lens is then manipulated into position using fine-pitched pusher screws. Using an Opto-Alignment LAS-P or similar […]

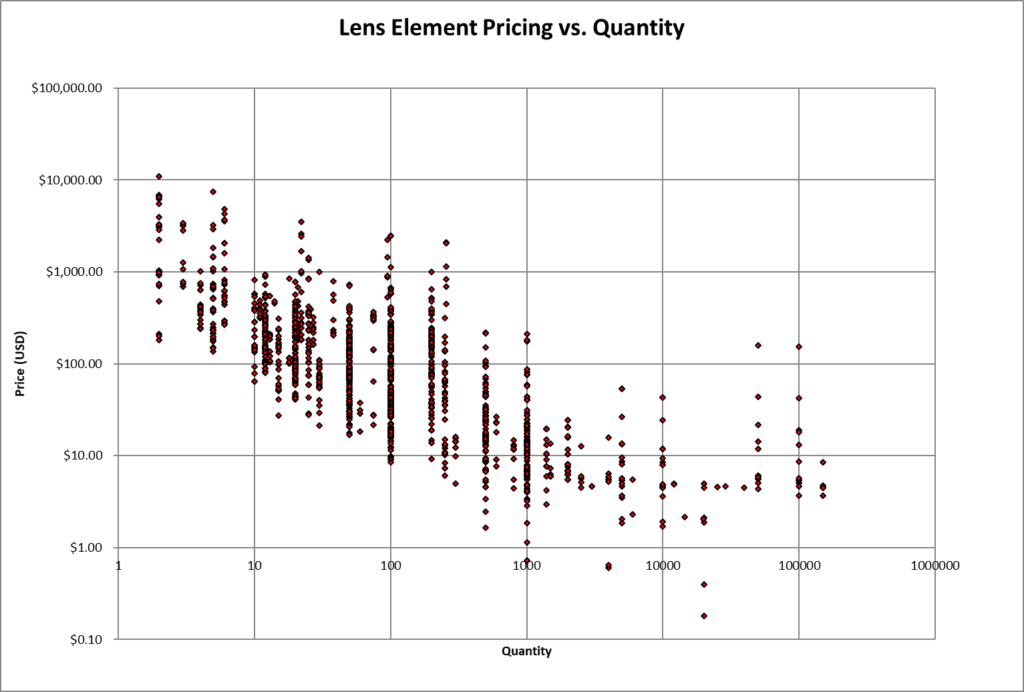

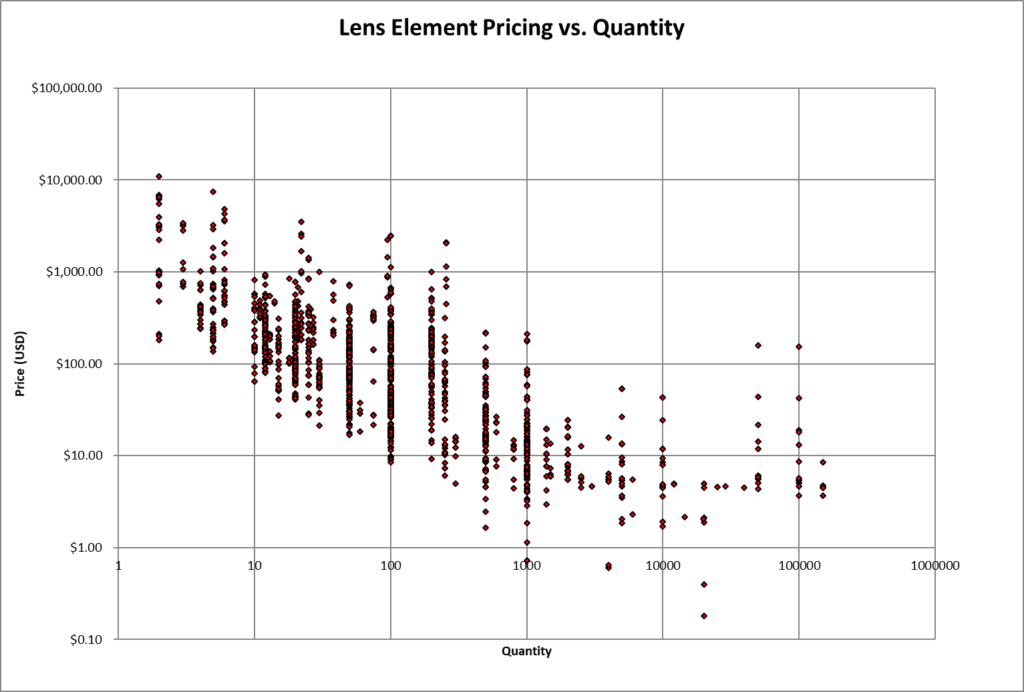

Reducing Cost in a Manufacturing Environment

In my previous blogs, I focused on the quality of the manufacturing processes both in In-Process Testing In a Production Environment and in Quality Statistics in Production: Using Data and Statistical Techniques to Improve Manufacturing Processes. While quality is essential to a successful manufacturing program, it cannot be taken in a vacuum without also looking […]

Quality Statistics in Production: Using Data and Statistical Techniques to Improve Manufacturing Processes

For those of you that read In-Process Testing in a Production Environment blog, this is the second installment in the series. Anyone who works in manufacturing understands the criticality of measuring the performance of sub-assemblies and finished products on a production line — and that’s where in-process testing comes into play. In my last post, […]

Lens Alignment as a Service at Optikos

What is active lens alignment? Active alignment is a process in which lenses are individually manipulated to bring them into alignment with a defined axis. Generally, this axis is based off of mechanical datums of a lens barrel. Each lens is then manipulated into position using fine-pitched pusher screws. Using an Opto-Alignment LAS-P or similar […]

Reducing Cost in a Manufacturing Environment

In my previous blogs, I focused on the quality of the manufacturing processes both in In-Process Testing In a Production Environment and in Quality Statistics in Production: Using Data and Statistical Techniques to Improve Manufacturing Processes. While quality is essential to a successful manufacturing program, it cannot be taken in a vacuum without also looking […]

Quality Statistics in Production: Using Data and Statistical Techniques to Improve Manufacturing Processes

For those of you that read In-Process Testing in a Production Environment blog, this is the second installment in the series. Anyone who works in manufacturing understands the criticality of measuring the performance of sub-assemblies and finished products on a production line — and that’s where in-process testing comes into play. In my last post, […]

Have a project in mind?

Reach out to us below to tell us a bit about your project.

Have a project in mind?

Reach out to us below to tell us a bit about your project.