Optikos is seeing continued interest in measuring stray light from our customer’s products and anticipates substantial growth in suppliers and end-users specifying and testing stray light performance. This is encouraging as it shows an increasing appreciation for the significance of stray light in optical imaging systems. The LensCheck instrument is an ideal and affordable instrument for enabling measurement of both Veiling Glare Index and Glare Spread Function.

Optikos LensCheck™ systems are designed to meet the increasing demand to measure the effects of stray light on optical imaging systems. Although unwanted light in a camera may pose a minor issue for the casual photographer, the resulting degradation in system performance in many industrial and automotive applications can represent significant financial costs, cause serious safety issues, or make or break a successful product launch.

Manufacturers are asking vision systems to take on more and more challenging imaging tasks across non-ideal imaging environments. Many applications require imaging scenes with extraordinarily high dynamic range content. For example, automotive cameras must be able to identify a pedestrian or traffic light at night while also imaging an on-coming car’s headlights. This performance must be determined while viewing through protective windows that may be scratched or covered with debris. Windows, debris, optical elements, and even the sensor can result in unintended radiation striking the detector. This light can potentially overwhelm the desired signal and introduce computational errors.

The designers, manufacturers and consumers of these lens and camera systems require a quantitative measurement of stray light. Optikos® products are designed to accurately perform these measurements.

The LensCheck system with OpTest® 7 software measures both Veiling Glare Index (VGI) and Glare Spread Function (GSF) to capture and assess the most critical or disruptive effects of stray light; and these measurements are also available through our in-house IQ Lab™ Services.

What is Stray Light?

Different terminology is used in different industries to describe stray light. Common terms are stray light, lens flare, veiling glare, ghost image, image glare, and many more. Most of these terms are not rigorously defined and will be interpreted differently by different readers. A useful introduction to stray light is provided in ISO 9358 – “Optics and optical instruments – Veiling glare of image-forming systems – Definitions and methods of measurement.” This standard is actively maintained (2014) and describes how to measure stray light in a lens assembly.

ISO 9358 includes the following definitions:

Veiling Glare – Unwanted irradiation in the image plane of an optical or electro-optical system, caused by a proportion of the radiation which enters the system through its normal entrance aperture. The radiation may be from inside or outside the field of view.

Veiling Glare Index – Ratio of the irradiance at the center of the image of a small, circular, perfectly black area superimposed on an extended field of uniform radiance, to the irradiance at the same point of the image plane when the black area is removed. VGI is expressed as a percentage unless otherwise specified.

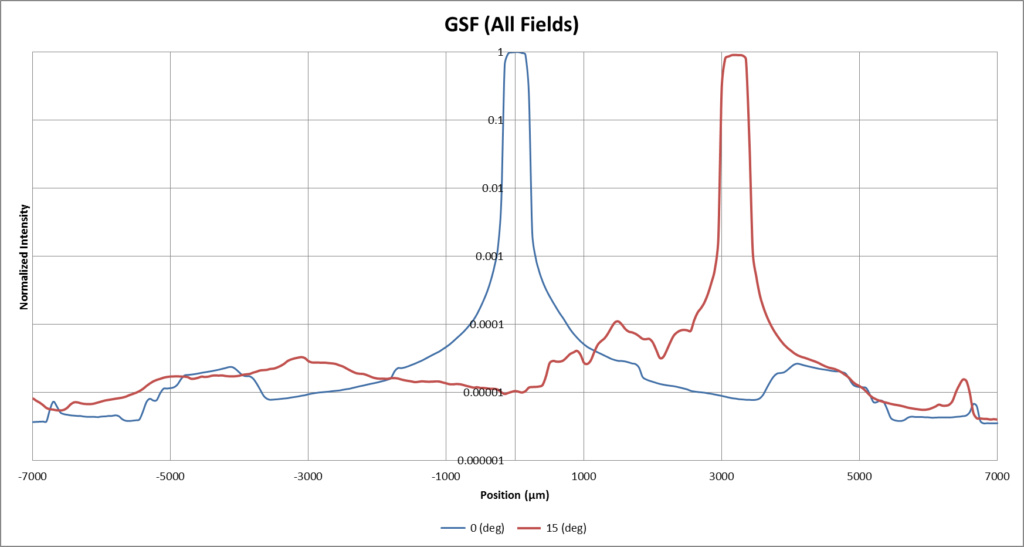

Glare Spread Function – Irradiance distribution in the image plane, produced by a small source object, normalized to unit total flux, in the on-axis image of the small source.

For the purposes of this discussion Optikos will primarily use the terms Veiling Glare and Veiling Glare Index (VGI), and Glare Spread Function (GSF). These measurements encompass all mechanisms of stray light.

How OpTest® Measures Stray Light

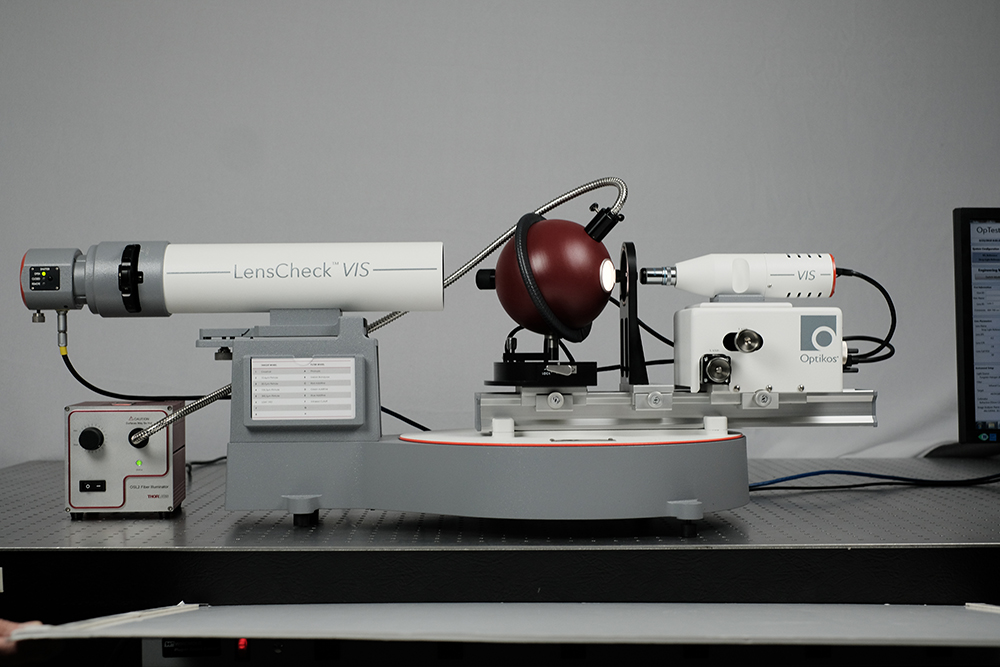

Many customers are interested in testing smaller optics for which the LensCheck™ test instrument is an appropriate choice. The LensCheck supports both the VGI and GSF stray light measurements using OpTest® 7 software. Both methods comply with ISO 9358.

A word on nomenclature: The Stray Light Kits offered for the OpTest and LensCheck instruments are designed for measurement of Veiling Glare Index (VGI). The GSF Kit is designed for measurement of Glare Spread Function (GSF). In both cases, the kits are designed for characterizing lenses. They are not intended for measurements on camera systems (lens + sensor).

Veiling Glare Index

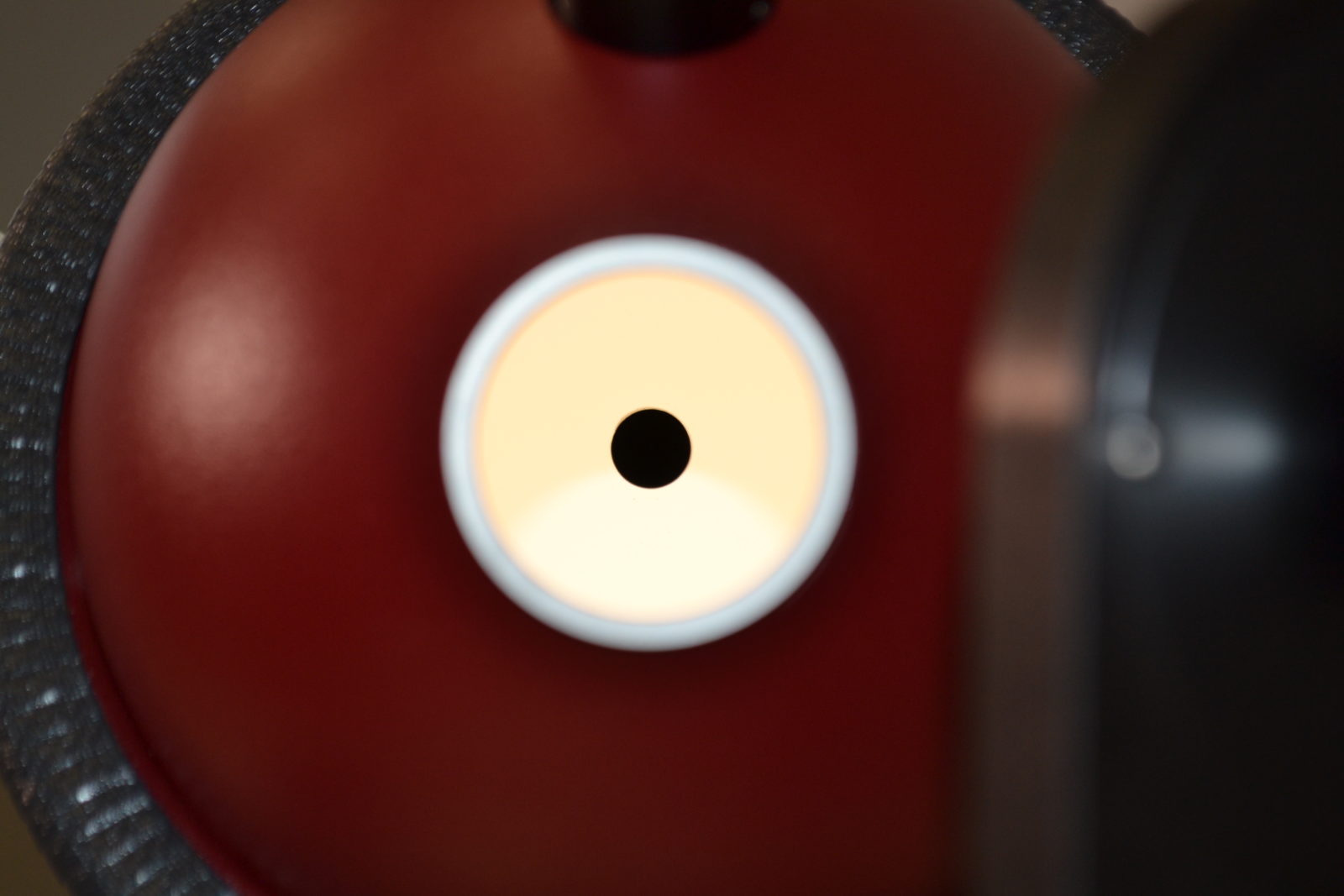

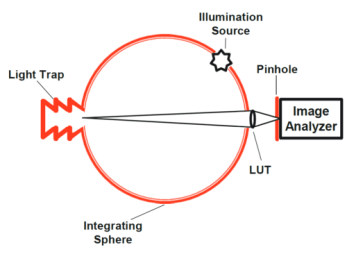

Veiling Glare Index (VGI) is a measurement of stray light reported as a single percentage value. VGI tests are performed without a camera or sensor in place. The lens under test (LUT) views a uniformly illuminated field that extends beyond the lens field. In practice this is usually accomplished by positioning the lens entrance pupil at exit port of an integrating sphere. A small, perfectly black object (light trap) is placed in the center of the field. A camera views the image plane, and the software measures the unwanted energy collected in the black area. This dark area signal is then compared to the surrounding bright signal. Small values of VGI are desirable.

Stray Light Kit schematic. The Lens Under Test (LUT) is placed at the exit port of the integrating sphere and creates an image of the light trap in its focal plane.

Optikos offers Stray Light Kits based on a 6”, 10”, or 20”integrating sphere. The 6” model, shown in the figure below, mounts directly on the LensCheck rotary platform. Stray Light Kits with 10” or 20” diameter integrating spheres will include an auxiliary rail structure.

How does the VGI measurement work with LensCheck and OpTest® 7?

To make a veiling glare measurement with the LensCheck Instrument, one needs to purchase one of the available Stray Light Kits. Each Stray Light Kit includes:

- Integrating sphere with an ultra-high absorption light trap

- 40X 0.65NA objective with precision pinhole field stop

- OpTest®7 upgrade to enable the VGI measurement module

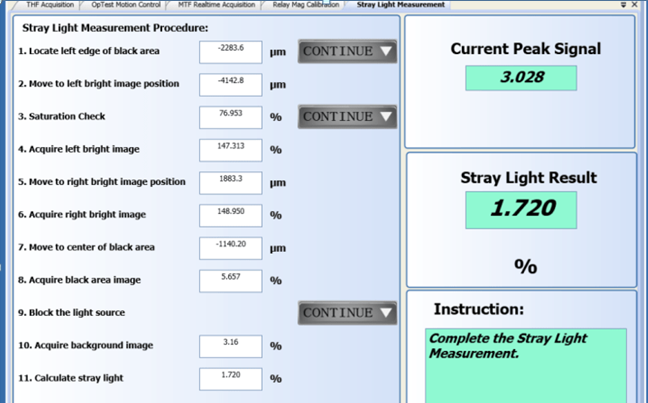

The Stray Light Kits are configured for both on- and off-axis measurements by mounting the integrating sphere on a rotation mechanism. Once the Stray Light Kit is installed, the OpTest 7 VGI software module automatically steps through a series of measurements to determine VGI by calculating the ratio of the intensity in the center of the image of the light trap “black dot” to the intensity of the surrounding white field.

The intensity of the surrounding white field is typically determined by averaging the white field on either side of the black dot in order to minimize the effects of any nonuniformity with in the sphere. As with all OpTest®7 modules, the data can be exported as a .CSV file or as a standard Excel document. Optikos has validated the stray light kit accuracy to 0.1%.

What lenses can I test with the Stray Light Kit?

The ISO standard recommends that the integrating sphere diameter be greater than 10 times the focal length of the lens under test. Therefore, the appropriate Stray Light Kit is determined by the range of lenses it is will be used to measured, as shown below.

- LC-SLK-06: Includes 150 mm Integrating Sphere for VGI measurements on lenses with focal lengths <15 mm

- LC-SLK-10: Includes 250 mm Integrating Sphere for VGI measurements on lenses with focal lengths <25 mm

- LC-SLK-20: Includes 500 mm Integrating Sphere for VGI measurements on lenses with focal lengths <50 mm

For signal-to-noise considerations, it is best to choose the Stray Light Kit with the smallest diameter sphere that satisfies the diameter ratio outlined above.

What are the limitations of the Stray Light Kit?

Longer focal length lenses can be difficult to test with the stray light kit as a complex geometry may be required to maintain the lens focal length to sphere diameter ratio.

It is critical that the test environment (laboratory, factory, etc.) be completely dark for accurate measurements. It may be necessary for the user to install light blocking curtains or enclose the instrument to block ambient light. There currently is no ISO standard for how dark the environment needs to be. Optikos can provide guidance on how to achieve an appropriate test environment.

The ISO specification defines VGI as an on-axis measurement. The black object is placed in the center of the field. Optikos has added off-axis measurement capabilities to our standard Stray Light Kits, allowing the beam dump (black dot) to be placed at up to +/-45 degrees off axis, through rotation about the lens entrance pupil.

Glare Spread Function (GSF)

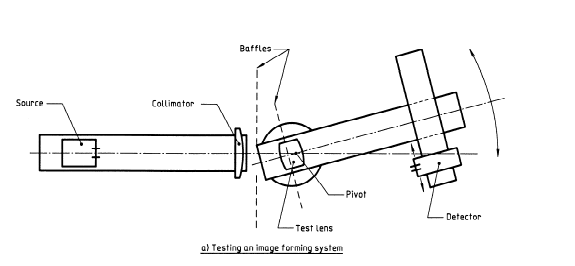

GSF is a measure of the irradiance distribution across the image plane when illuminated with collimated light at a specific angle of incidence. This requires a source and collimator, as well as a rotary platform to set the incident angle. The test conditions for GSF are determined by the user, and GSF can be recorded for a range of incident angles or a single angle.

Glare Spread Function schematic. The Lens Under Test (LUT) is rotated to the selected angle of incidence (field angle). The image analyzer then translates across the image plane.

How does the LensCheck’s new GSF measurement work with OpTest 7?

OpTest® 7 software now includes an automated Glare Spread Function measurement when used with the LensCheck GSF Kit. The GSF Kit and OpTest 7 module allow characterization of GSF artifacts generated within the lens itself. It is not intended for measurements of full camera systems (lens + sensor).

The GSF Kit includes:

- 40X 0.65NA objective with precision pinhole field stop

- Light guide adapter with diffuser and small exit aperture to minimize scattered light within the LensCheck collimator itself

- 1mm and 3mm pinhole targets

- OpTest®7 upgrade to enable the GSF measurement module

The GSF measurement module allows the user to select the size of the image plane to measure, what the step size will be, and at what source angle to make measurements. The automated module will adjust and record the exposure appropriately at each step in addition to collecting the signal value. The GSF is plotted by OpTest®7 as the normalized intensity by position. The GSF Kit can be used on both the infinite conjugate and finite conjugate LensCheck instruments.

On what lenses can I measure GSF?

The Glare Spread Measurement may be performed on any lens that can be tested by LensCheck—clear apertures up to 50mm, focal lengths between 1mm and 200mm.

What are the limitations of the GSF measurement?

The ultimate limitations of the GSF measurements are related to the dynamic range of the detection system. OpTest systems use a combination of high-dynamic range CCD cameras and exposure algorithms that allow characterization of image artifacts with relative intensities down to 10-5.

As is the case with VGI measurements, it is critical that the test environment (laboratory, factory, etc.) be completely dark for accurate GSF measurements. It may be necessary for the user to install light blocking curtains or enclose the instrument to block ambient light. There currently is no ISO standard for how dark the environment needs to be. Optikos can provide guidance on how to achieve an appropriate test environment.

Is it best to measure GSF of the lens or camera?

An important distinction arises when measuring the GSF of the lens or the camera (lens + sensor). The ISO 9358 standard only specifies testing a lens assembly and not a camera, but these two tests can produce very different results because the camera itself can contribute significantly to stray light. Reflections off of the cover glass, sensor, mount and mechanics produce unwanted irradiation. Furthermore, the sensor itself can contribute random and fixed pattern pixel noise, readout errors such as blooming, residual images, electron drift and crosstalk, and other phenomena that play a significant role in perceived stray light. As mentioned above, the Stray Light Accessories described in this document were designed to characterize lenses, not full camera systems.

Veiling Glare Index or Glare Spread Function?

Both VGI and GSF can be valuable tests. VGI is useful as a measure of diffuse irradiance on the image plane. Poor VGI is commonly seen from poor coatings or insufficient baffling and produces a general loss of contrast. The VGI is easily specified by a single percentage value and is a quick and easy measurement. It is very effective for comparing lens performance across suppliers and for use in lens specifications. Many MIL specifications, such as for image-intensifier tubes, require VGI testing.

GSF is particularly useful to evaluate severity of ghost reflections or other prominent stray light artifacts that form concentrated irradiation patterns. The GSF test is more time consuming but also provides more insight into the origin of stray light issues. This is particularly valuable to the optical and opto-mechanical designer. Because of the inherent high sensitivity of a GSF measurement, it is useful for challenging imaging environments that are sensitive to stray light, such as evaluating the impact of windows on automotive cameras, airborne cameras, or LIDAR systems.

Summary

Optikos is seeing continued interest in measuring stray light from our customer’s products and anticipates substantial growth in suppliers and end-users specifying and testing stray light performance. This is encouraging as it shows an increasing appreciation for the significance of stray light in optical imaging systems. The LensCheck is an ideal and affordable instrument for enabling measurement of both Veiling Glare Index and Glare Spread Function.

Stray Light Product Offerings

Veiling Glare Index (VGI) Kits

| LC-SLK-06 | Includes 150 mm Integrating Sphere for VGI measurements on lenses with EFL <15 mm |

| LC-SLK-10 | Includes 250 mm Integrating Sphere for VGI measurements on lenses with EFL <25 mm |

| LC-SLK-20 | Includes 500 mm Integrating Sphere for VGI measurements on lenses with EFL <50 mm |

Glare Spread Function (GSF) Kits

| LC-GSF | Expands capability of the Standalone LensCheck VIS to measure GSF. Better than 10-5 dynamic range for broadband visible test spectrums |

Get Started with Optikos

Optikos offers metrology products and services for measuring lenses and camera systems, as well as engineering design and manufacturing for optically-based product development. Our full-line of standard products for testing optical, image and camera systems are appropriate for any industry and we will design a custom product for your specific application. Visit our website at optikos.com, email us at sales@optikos.com or give us a call at +1 617.354.7557 to learn more.