Product Development

Product Development

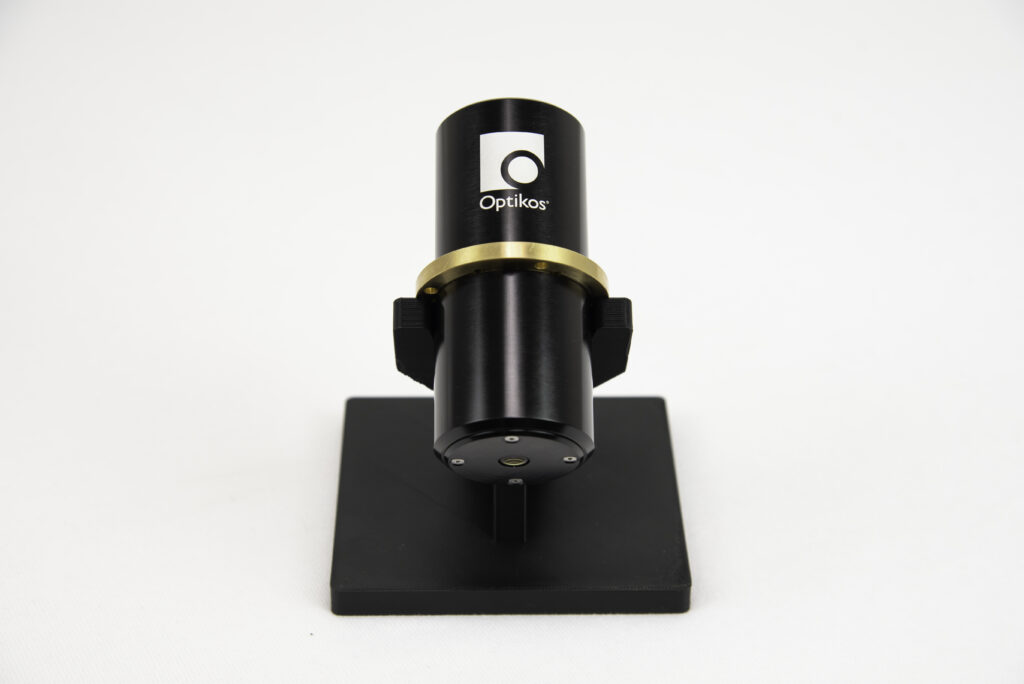

Our core competency in optical engineering allows us to provide optically-based design for any product or application

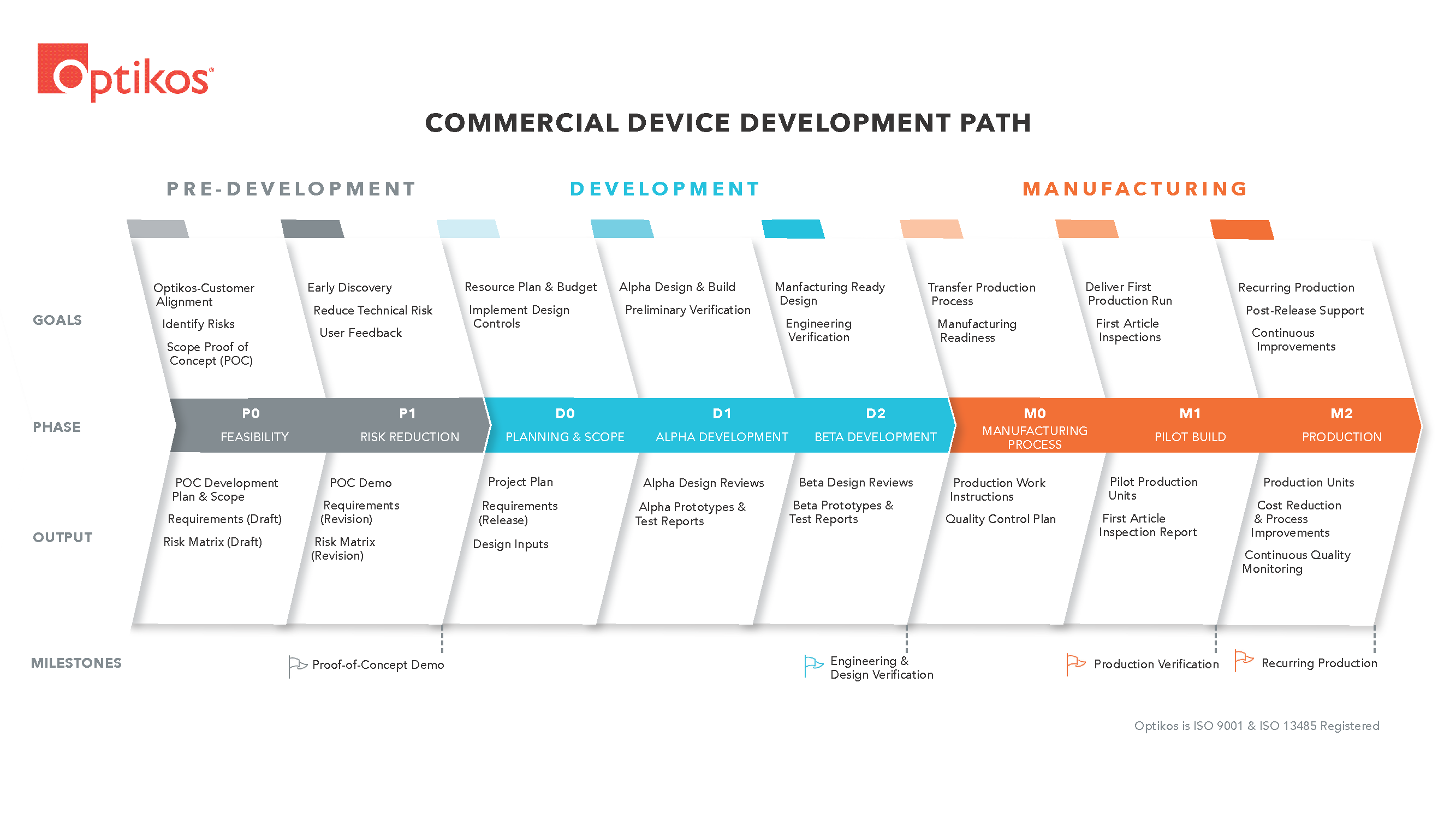

Where other optical consulting firms might offer only lens design services, Optikos has built its reputation on providing our clients with access to broadly skilled optical problem solvers who provide solutions and continuity of support throughout the product development cycle.

Your design can range from any single a là carte technical solution to complete product development through manufacturing.

And at project completion, you own the design.

The Optikos Management System is registered by Intertek as conforming to the requirements of:

Our core competency in optical engineering allows us to provide optically-based design for any product or application

Where other optical consulting firms might offer only lens design services, Optikos has built its reputation on providing our clients with access to broadly skilled optical problem solvers who provide solutions and continuity of support throughout the product development cycle.

Your design can range from any single a là carte technical solution to complete product development through manufacturing.

And at project completion, you own the design.

The Optikos Management System is registered by Intertek as conforming to the requirements of:

Diverse Skillsets offer Efficient Problem Solving

Diverse Skillsets offer Efficient Problem Solving

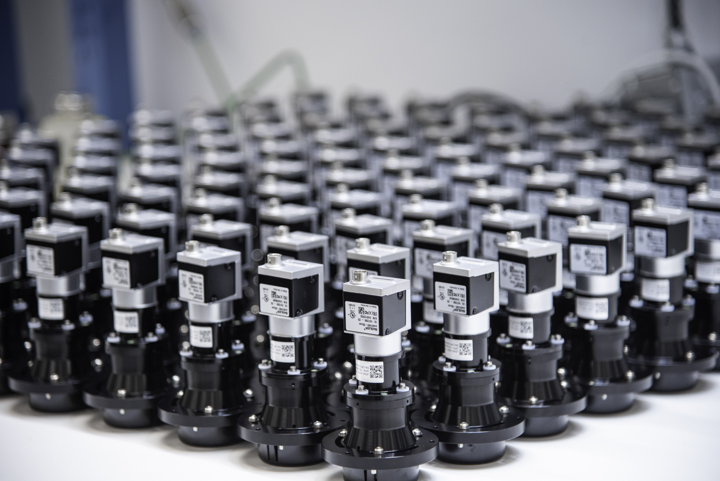

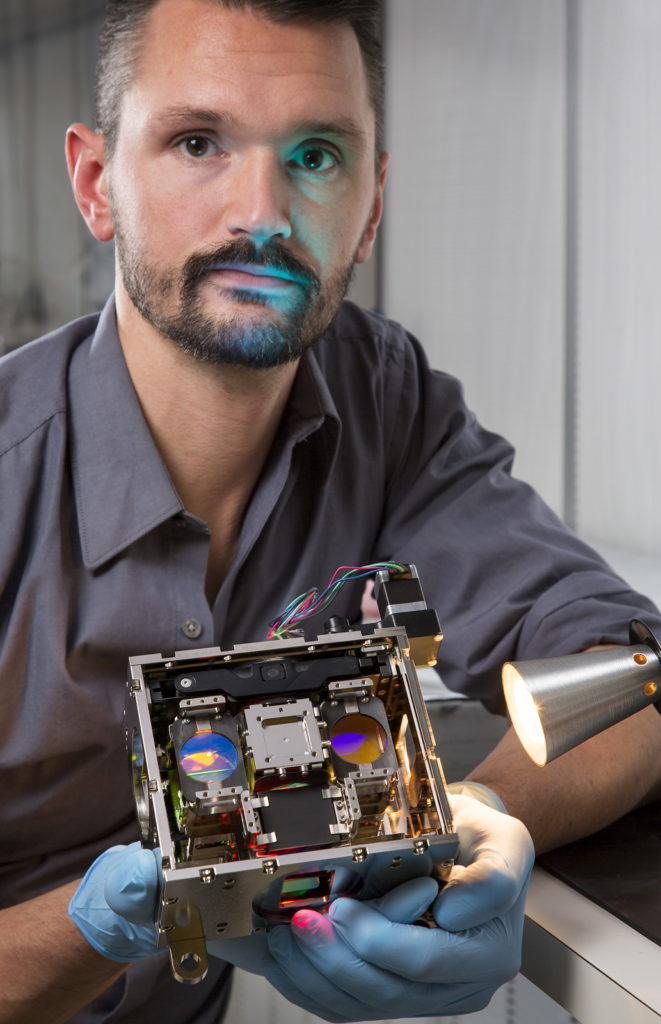

Optikos engineers team up according to the demands of the job—bringing together specialties not only in optics, but also in physics, mechanics, opto-mechanics, electronics, software, and automation.

These diverse teams and skill sets enable Optikos to offer a range of engineering skills and experience for optically-based product development that is not typically encountered or developed in most in-house engineering departments or independent consultancies.

Our engineering teams thrive in a culture of efficient problem solving, and are experienced at joining a project at any phase of the development cycle—from conceptual work to fixing existing products that don’t work. We understand the sometimes-unpredictable nature of moving products to market and we’re well-prepared to deal with it.

Optikos engineers team up according to the demands of the job—bringing together specialties not only in optics, but also in physics, mechanics, opto-mechanics, electronics, software, and automation.

These diverse teams and skill sets enable Optikos to offer a range of engineering skills and experience for optically-based product development that is not typically encountered or developed in most in-house engineering departments or independent consultancies.

Our engineering teams thrive in a culture of efficient problem solving, and are experienced at joining a project at any phase of the development cycle—from conceptual work to fixing existing products that don’t work. We understand the sometimes-unpredictable nature of moving products to market and we’re well-prepared to deal with it.

A Flexible Resource

You can work with Optikos at any point in your product development process, whether you need one specific service or a one-stop-shop. We offer a flexible, scalable resource that helps you fill a competency gap when you need it, so you can focus on the business you’re in.

A Flexible Resource

You can work with Optikos at any point in your product development process, whether you need one specific service or a one-stop-shop. We offer a flexible, scalable resource that helps you fill a competency gap when you need it, so you can focus on the business you’re in.

Hear It from the Optical Engineering Experts®

Expert-written blogs from our on-site engineering staff.

Hear It from the Optical Engineering Experts®

Expert-written blogs from our on-site engineering staff.

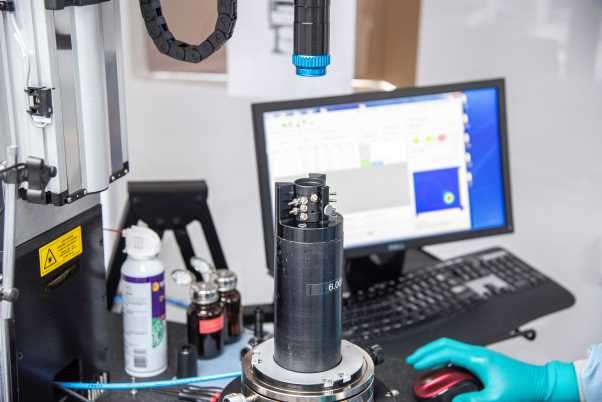

Lens Alignment as a Service at Optikos

What is active lens alignment? Active alignment is a process in which lenses are individually manipulated to bring them into alignment with a defined axis. Generally, this axis is based off of mechanical datums of a lens barrel. Each lens is then manipulated into position using fine-pitched pusher screws. Using an Opto-Alignment LAS-P or similar […]

Time for a checkup! How IQ Lab™ Services Keep Your Lenses and Cameras Healthy

It’s that time again – time to head to your doctor’s office for a checkup. You arrive and a medical assistant calls you to the back. Before your doctor comes in, you have your blood pressure checked, your heart rate measured, temperature taken, and maybe even have some blood drawn. These are part of a […]

What is a Microscope Objective? An introduction to objective lenses.

A microscope objective refers to the lens(es) closest to the object in a microscope. The term microscope objective is often used interchangeably with objective lens, or known simply as an objective. The objective works with the tube lens and/or eyepiece to project the image of the subject into an image sensor or the viewer’s eye, […]

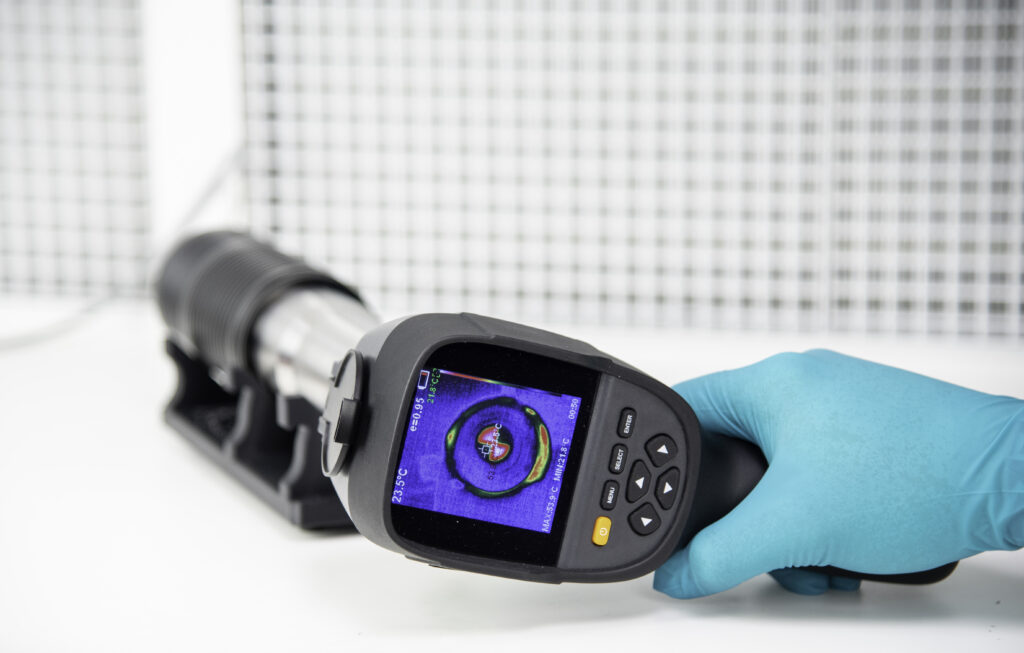

Some Overlooked Thermal Considerations When Mounting Lenses For Aerial Imaging Applications

Aerial imaging applications present a unique challenge when considering thermal environmental changes. A system can experience extremely low temperatures while at altitude and extremely hot temperature while waiting and taxiing on hot tarmac. If the environmental changes are not fully considered early in the design phase, then the system is likely to suffer from performance […]

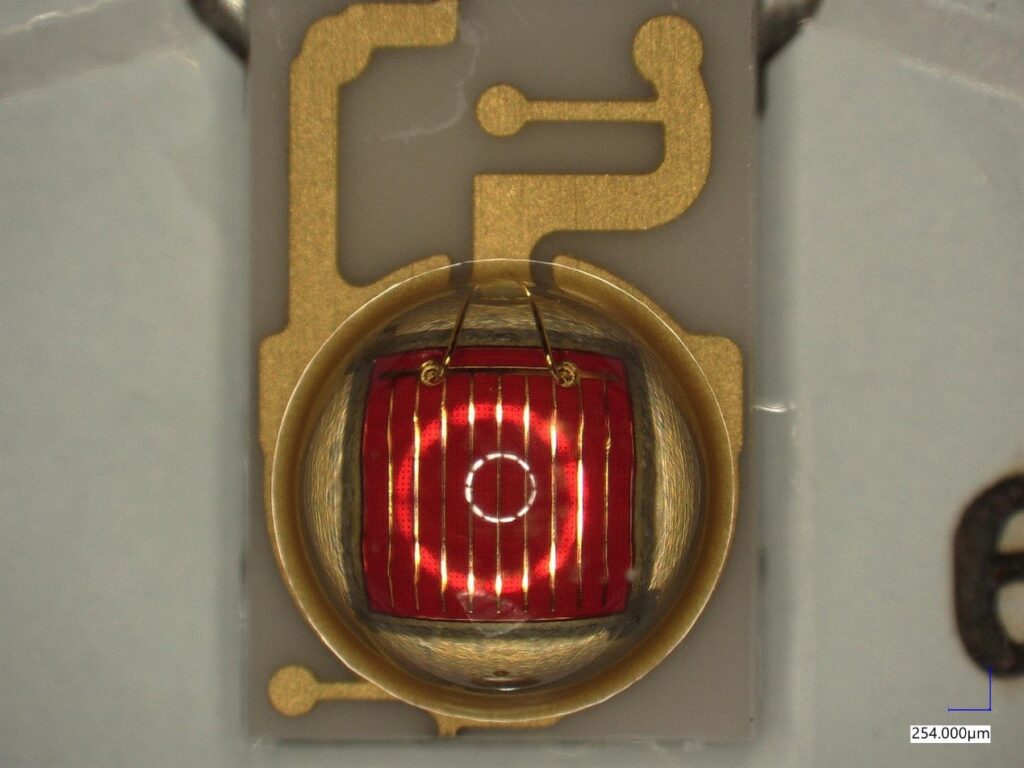

Pitfalls in Selecting LEDs for Quantitative Devices

In the world of visible light sources, it’s hard to beat light emitting diodes (LEDs). These tiny emitters are mass produced in countless varieties of color and intensity, making them the obvious choice for a device that requires a lot of light at specific wavelengths. Often there are dozens of candidates that would produce acceptable […]

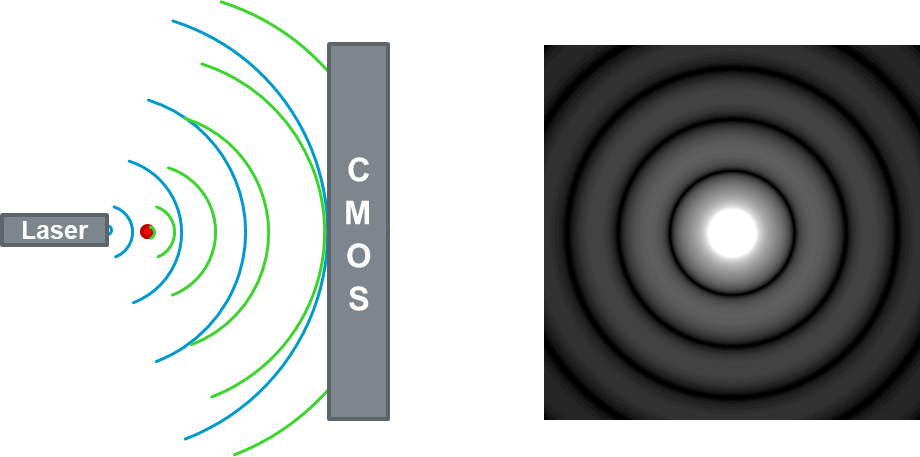

Lensless Imaging – Hype or the Future?

Optikos touts ourselves as the Optical Engineering Experts™, so it’s always interesting when a customer approaches us to remove optics from their system! We’ve had a variety of interested parties engage Optikos about lensless imaging. This is a novel approach to imaging that removes the optical lens, while still generating high quality images using computational […]

Let's Get to Work.

Use the form below to reach out and tell us a bit about how we can assist in your next project.

Let's Get to Work.

Use the form below to reach out and tell us a bit about how we can assist in your next project.