What is active lens alignment?

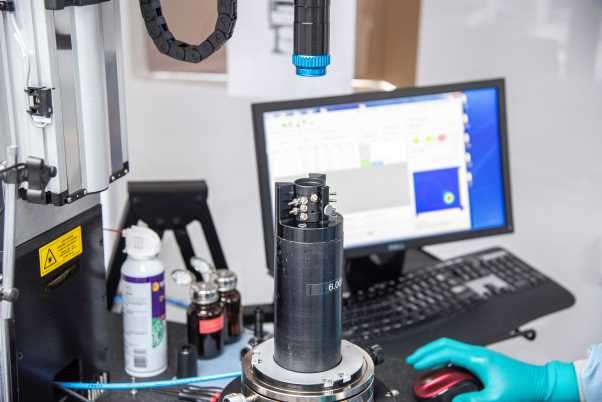

Active alignment is a process in which lenses are individually manipulated to bring them into alignment with a defined axis. Generally, this axis is based off of mechanical datums of a lens barrel. Each lens is then manipulated into position using fine-pitched pusher screws. Using an Opto-Alignment LAS-P or similar device, the lens centration and tilt can be measured during this process. Realtime feedback allows the position of the lens element to be centered to single-digit-micron level (design dependent). Once the lens is in position, it can be held with retainers, adhesives, or a combination of both. This process is done one lens at a time until the entire lens stack is centered to the common optical axis.

When is active lens alignment required?

When designing a lens assembly, part of the tolerancing analysis is how well-aligned each lens must be in relation to their nominal position to achieve the desired imaging performance. The result of the tolerancing analysis determines what build methods can be selected for the lens stack. Lens centration of 25 microns or greater are generally easily achieved through mechanical tolerancing of lens barrels and component lenses. When lens centrations of <25 micron are required, it is time to start considering active alignment.

Active Alignment in Production

Active alignment can be used in a production setting to build lenses with very demanding performance requirements. To efficiently use active alignment techniques in a production setting, the design phase needs to address reduced touch time in the alignment process. This effort is used to appropriately tolerance lens diameters and wedges as well as the barrel inner diameter and lens seats. Thought must be put into whether lenses are interfacing with the barrel on a flat or curved surface as this will impact how a lens moves relative to the barrel while being positioned. In some cases, active alignment can be used in conjunction with our alignment turning machine to create lens cells that can be actively or passively centered to each other. To learn more about our alignment turning capabilities, please see our previous blog post A Tale of Three Lenses: How Alignment Turning Creates Accurate Imaging Systems for Less.

Our history

Optikos has offered Lens Alignment as a service for 10 years and is proud to use machinery from Opto Align, the premiere manufacturer of alignment tables. Our trained staff are experts at using the LAS-P-VIS & LAS-P-VIS-IR models. While the LAS-P-VIS model is used for visible lenses, the LAS-P-VIS-IR model is utilized for alignments of both visible and infrared lens assemblies. To learn more about these stations, you can visit their website.