Optikos buys a lot of lens elements and builds a lot of lenses. We use them in the engineering design and manufacturing work we do for clients—from prototype builds to long-run production volumes in the 10’s of thousands.

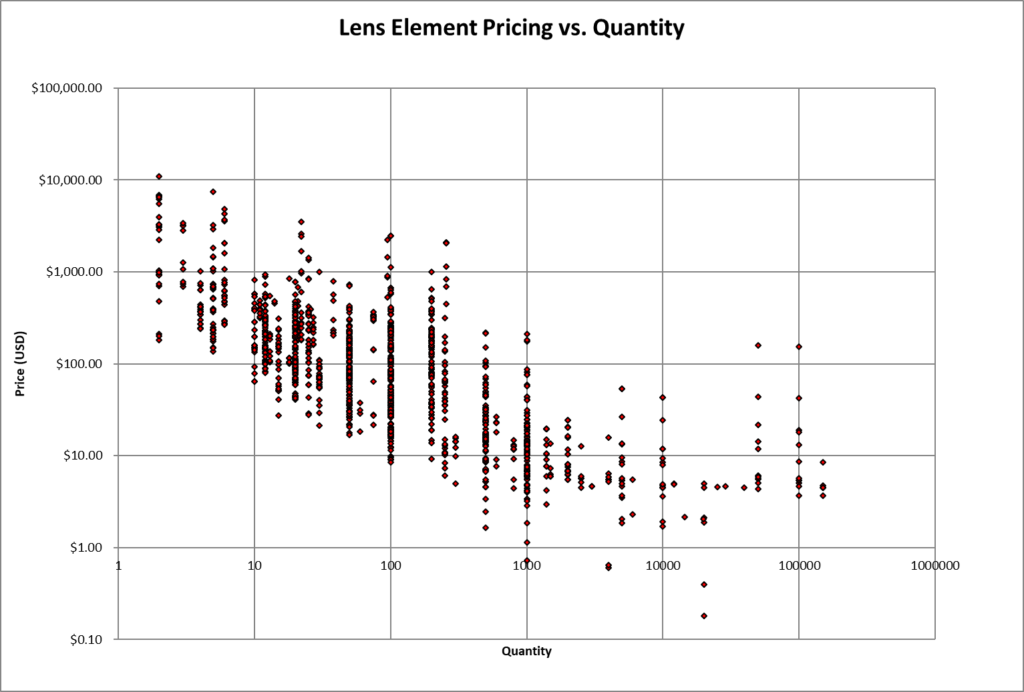

We’re a little different from other manufacturers—we don’t specialize in just infrared optics, or low-cost optics, or projection lenses, or any other specific market. We routinely purchase diamond turned plastic lenses, molded optics (glass and plastic), polished glass spheres and aspheres, doublets, triplets, cylinders, domes, IR lenses, UV optics, and so on. I’ve been tracking pricing from our quotes for a while now, and, while we won’t share all the details, I can share an overarching plot of lens price vs. volume that definitely supports the cost advantages derived from economies of scale in purchasing lens elements.

Note that this includes ALL kinds of optics—all diameters, all glass types, all manufacturing methods, all tolerances. The price is per element—a typical lens design may have anywhere from 1 doublet to a dozen or more. Size can be measured in single millimeters or in inches. I’ve tried to omit NRE or tooling charges except when that has been baked into the price. Vendors span the globe. The only omitted data are mirrors and prisms. Note the LOG scale of the y-axis.

If you ask Optikos for a project proposal we are able to rely on four decades of sourcing and purchasing experience, and we’re likely using this data to help estimate prototype and production costs for the systems Optikos designs and builds.

Return to Anywhere Light Goes blog.

Written by Haskell Kent, Optikos Corporation