In our last post we highlighted product develop strategies for high-end optical subsystems. In this post we’ll move to the other extreme – ultra low-cost optics in mass produced systems.

Consumer Grade Products

To start, we should appreciate that while a mass market optical system may not have the performance of a DNA sequencer, the product development tradespace can be just as challenging. Optikos has regularly designed optical systems for toys; what could be simpler? Toys require next-to-nothing manufacturing costs, typically require compact packaging, must exhibit decent optical performance (better than you may think), and have to survive being thrown in the toy bin or run over by the Barbie 4-wheeler. In short, toys are not easy to design.

To hit the price target optics and mechanics have to be molded without fail. Fortunately, this leads us to diamond turning. Diamond turning is a method of rapidly producing plastic optical components – this is great for simulating molded lenses in small quantities. Similarly, rapid plastic molding (non-optical molding) can produce optically acceptable parts in more unique shapes. This is useful to vet light pipes and similar.

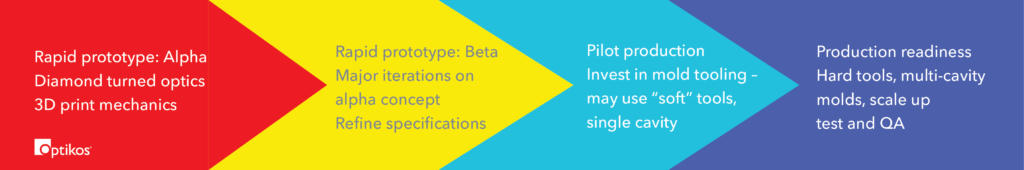

Don’t have fully fleshed out product requirements? No problem! In this market fail-fast can work great and we encourage a jump straight to alpha prototype. Diamond turning optics, machining plastic housing, and hooking up a control PC in place of on-board electronics, can allow you to put a functional prototype in front of your users (or investors) in a few short weeks.

The alpha prototype allows quick user feedback to advance product requirements, and usually illuminates risks that need to be more carefully considered during following design phases. A more sustained beta development phase can then take place, with one or more prototype iterations to follow. During these phases it is critical to undertake a thorough optical tolerance analysis before committing to molded parts. Despite being nominally equivalent, diamond turned optics often exceed molded part tolerances. This raises the risk of building functional prototypes and non-functioning production units.

At pilot production we recommend investing in injection mold tooling for all optical and mechanical components – this is a substantial expenditure but at this point you should have a high-level of confidence in the design. If schedule is a concern “soft” tools can be used which have limited lifetime. Then full production scaling can occur during Pilot validation.

To summarize, for low-cost and high-volume designs utilizing molded optics:

- Start designing with preliminary specifications.

- Take a rapid path to alpha prototypes – diamond turn optics, 3D print or machine mechanics, cobble together electronics via PC control, raspberry Pi, and other existing platforms.

- Iterate product requirements based on alpha feedback, identify major technical risks.

- Continue development/build cycle until satisfactory outcome.

- Invest in mold tooling only before Pilot production.

- Perform careful verification of pilot parts – ensure proper quality processes at overseas manufacturers.

- Establish continuous AQL criteria at suppliers and CM to ensure production quality is maintained.

Conclusion

In Part I we presented a high-end optical system. In Part II we’ve highlighted a low-cost, potentially non-imaging optical system. The reality is that your product development is likely in between these extremes. In this case we always work closely with our customers to help collectively determine where we should push for cost reduction or schedule, or where to invest that time or money for a longer-term return.

Finally, some recommendations that we’ve learned over time:

Rapid optical production capacity is limited – the global capacity for lens manufacturing is limited. The shop that says they can make your optics in 2 weeks may receive a big order and balloon that delivery to 6 weeks or more. You can never take production lead times for granted, and as a result we often perform risk buy for optics even when the system design is not finalized.

Glass can kill you – if you’re pursuing a custom optical design, realize that some glasses have very limited availability and/or bi-annual melts. This means that you may not be able to get parts for 6 months or more. The smart designer evaluates material availability before designing the glass into their system. This goes for diamond turned plastics as well (although less extreme) – often procuring the raw material takes longer than the manufacturing time.

Buy spares – if one lens breaks your project is dead in the water for weeks. The risk mitigation by buying an extra set of optics is a no brainer.

Don’t underestimate precision mechanics – woe is the engineer who locks down a good glass vendor but ignores the precision opto-mechanics. Precision machining is arguably more widely available, but expert opto-mechanics shops are in high-demand and are worth their weight in gold. They often run leadtimes as long (or longer) than glass.

Conclusion

In conclusion, the world of electro-optical hardware has its own unique challenges. No one product development strategy applies to all projects and this is particularly true for optical products. Optikos is always ready to take on an impossible challenge, whether technical or schedule, and guide our customers to success.

Return to Anywhere Light Goes blog.

Written by Haskell Kent, Optikos Corporation