In my previous blogs, I focused on the quality of the manufacturing processes both in In-Process Testing In a Production Environment and in Quality Statistics in Production: Using Data and Statistical Techniques to Improve Manufacturing Processes. While quality is essential to a successful manufacturing program, it cannot be taken in a vacuum without also looking at cost.

For a successful manufacturing relationship, the manufacturer must make a quality product while minimizing cost and giving the customer a great overall value. At Optikos, we employ LEAN principles in order to reduce touch time and offer a cost competitive manufacturing solution to our customers. We also utilize our domestic and global supply chains to reduce material cost.

Reducing Touch Time

In order to reduce touch time, we employ LEAN principles on the manufacturing floor. Our goal is to eliminate as much waste from our processes as possible. To achieve this, we minimize defects, idle time, extra processing, transportation, and motion.

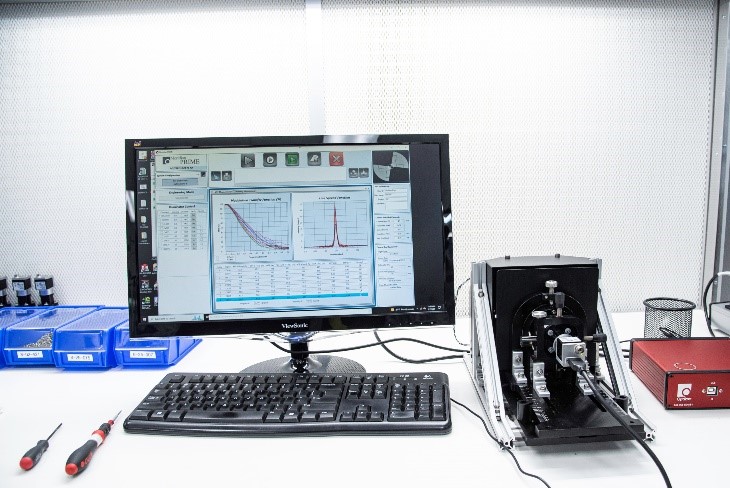

For example, here is one of our manufacturing work stations. We use LEAN principles and set up each work station so that all necessary tools are clearly marked and located at the point-of-use. We have customizable tool boards that allow us to quickly set up and break down stations with the tools needed for each unique project.

Furthermore, for high volume builds that require higher levels of documentation, we implement a barcoding system on our torque wrenches and adhesives. This allows our assemblers and technicians to quickly scan the tool being used to capture calibration or expiration dates without having to spend extra time on paper work. Once in production, this technique reduces wasted movement and allows our team to build product rapidly.

Another way we reduce touch time is through efficient testing and defect detection. In an earlier blog, In-Process Testing in a Production Environment, I discussed how we pair alignment and testing steps together to efficiently get a final functional test without adding time to our alignment process. Using in-process testing at a sub-assembly level ensures that we are finding defects early in the process; This reduces material scrap and the touch time required for re-work.

At Optikos we will look at the time it takes to run the in-process test, the defect rate, and the time saved per defect found and perform a cost benefit analysis of performing that in-process test. It is great to find defects early, but we need to make sure that this process ultimately saves time.

For example, if we have a 2-minute test to identify defect, and a 1% defect rate, we would need each defect found to save 200 minutes of rework time (or the equivalent material scrap cost)! If the defect rate is 2% the amount of time needed to be saved to be worthwhile drops to 100 minutes. Depending on the complexity of the build in question, running this test may be a huge efficiency gain or loss. Each line is evaluated for where in-process testing makes sense.

Reducing Material Cost

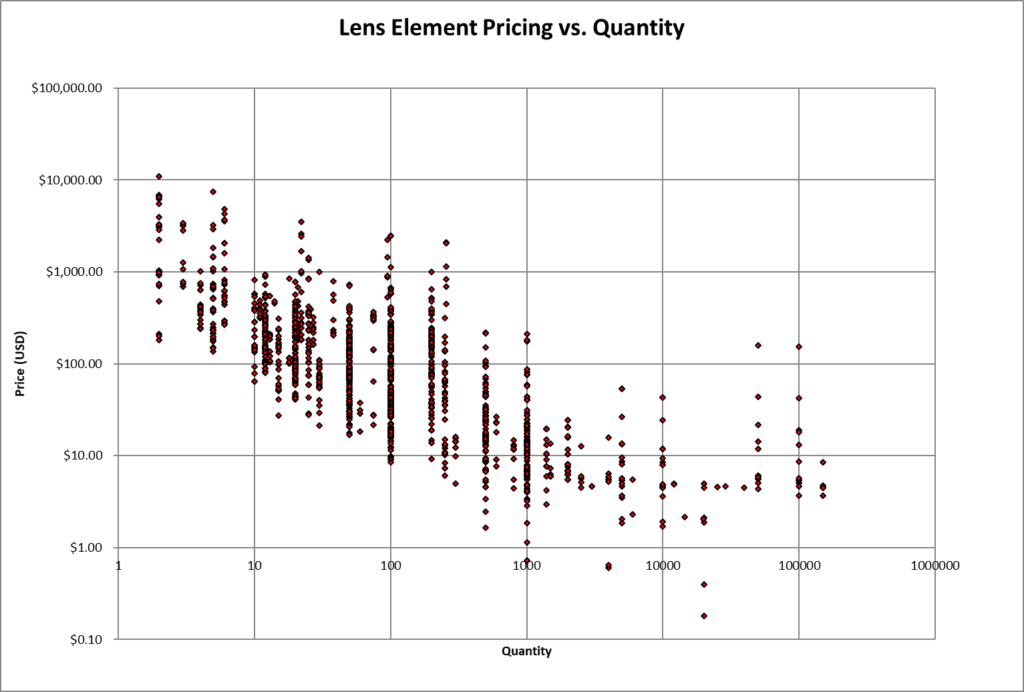

In a previous blog, Lens Element Pricing Benefits from Economies of Scale, we showed a large data set of lens element prices and how they reduced with volume. By outsourcing our lens components, we are able to select the appropriate vendor for a given lens design and not be constrained by our internal fabrication capabilities. Whether we are procuring traditionally grind and polished spherical lenses, aspheres, molded glass elements, or molded plastic elements, we can select the appropriate vendor to source high quality components at competitive prices. We use the same strategy with our mechanical and electrical component procurement as well.

Optikos has a supply chain that spans both domestic and overseas suppliers to meet our clients’ needs. Our customers in the defense space often have ITAR restrictions which require domestically procured components. For customers not limited to domestic constraints, we are able to utilize our overseas supply chain to find the best selection of quality and price for each component that the world has to offer.

Want to see this in action? Take a virtual tour of our Manufacturing Facility, located in Wakefield Massachusetts.