The AM-1000 is the current generation Optikos® precision image analyzer mount, positioning the image analyzer at the image plane of the lens under test. It is composed of three stages that move along three orthogonal axes and position the optical axis of an image analyzer coincident with the optical axis of the entire test system.

All three axes feature high precision crossed roller bearing stages with stepper motor driven lead screws. Axis positioning is enabled via integrated optical 50nm encoders, supported by optical non-contact limit and home switches. The AM-1000 integrates directly with the OpTest® bench CANbus protocol, adding component level intelligence to enable single-wire communication for multiple axes of travel.

A stainless steel dovetail mount allows for reliably interchanging different image analyzers and other components on and off of the AM-1000 assembly. Additional mounting holes are located in both fixed and mobile locations on the AM-1000 package for mounting indicators, brackets, alignment tools or other application specific components.

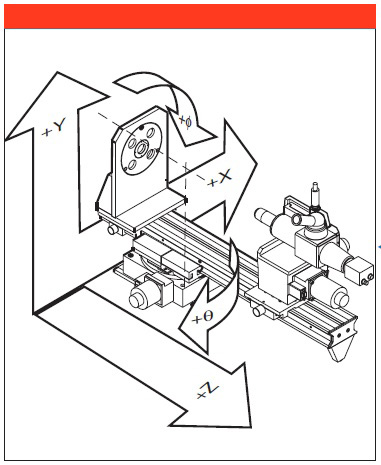

Image analyzer mounts define the following three-axis convention in the image space of the lens under test:

- X adjusts the lateral image height parallel to the optical table

- Y adjusts the image height perpendicular to the optical table

- Z is the focus adjustment along the optical axis

Sign Conventions

It is important that the operator understand the sign conventions used in OpTest® systems. The adjacent figure illustrates the direction of increasing positive movement of some of the more frequently motorized axes in a system. The sign convention may best be understood by imagining that the coordinate system is attached to the lens under test, not to the optical table. As the lens is rotated clockwise through an angle θ with respect to the table, the object will appear to have rotated counterclockwise from the point of view of the lens, just as it would do in a conventional right-handed Cartesian system.

High Resolution Image Analyzer Mounts

Motorized axes of the high-resolution image analyzer mounts feature the following performance specifications:

| 1 | X and Z Axis Total Travel | 100mm (customizable up to 200mm) |

| 2 | Y Axis Total Travel | 50mm |

| 10 | Encoder Resolution | 50 nm |

| 12 | Operating Temperature | 15-30 deg C (laboratory environment) |

| 13 | Storage Temperature | -20-50 deg C (shipping) |