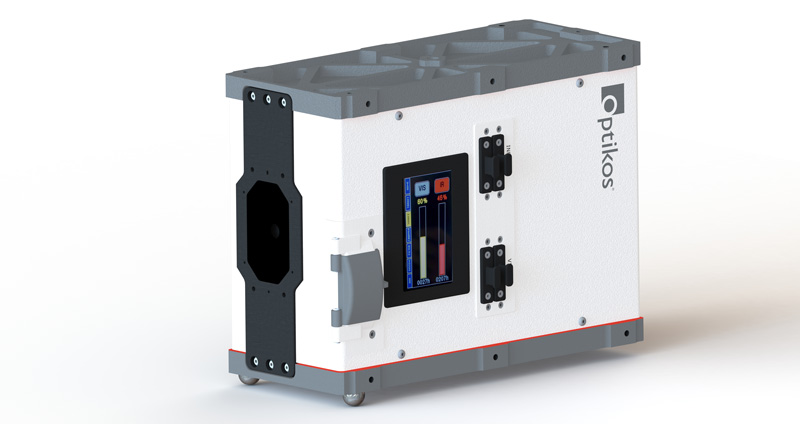

A Family of Intelligent Object Generators

Microprocessor Control

In MTF testing, a member of the newly designed OG-1000 family of object generators presents the lens under test with an object of known spectral and spatial content. This state of the art object generator integrates visible and infrared light sources, spectral filters, condensing optics, chopper wheel, automated shutter, and a motorized target wheel with laser-cut apertures in a single instrument. All object generator functions including source selection, linear current control, chopper speed and position, target selection, and shutter position are internally controlled and monitored by a high-speed microprocessor. A built-in color touchscreen allows the user to adjust any of these parameters with ease while multiple electronic interfaces including RS-232, RS-485 and CANbus permit remote operation by a host computer or the HC-1000 handheld controller. Ancillary functions such as thermal management and source on-time logging are also performed by the microprocessor.

Mechanical Interface

A kinematic interface may be affixed to one of three mounting surfaces, thereby ensuring that the touchscreen is always user-accessible regardless of where the target generator is located on the test bench. Optional riser assemblies provide the mating interface and set the target aperture at the required height above the optical table. The object generator detects the mounting orientation and ensures that the display is always upright. The intelligence of the OG-1000 extends to a high degree of self-awareness. For example, all target calibration data is stored within the object generator, and when the mounting configuration rotates 90°, slits that were previously vertical are now reported as horizontal.

Light Source

One of the key features of the infrared object generators is the inclusion of a co-aligned visible source that may be switched in at the press of a button or the issuance of a single command. Together, these sources provide uniform, high intensity illumination from the visible to long wave infrared (400nm-15 μm). Users who are experienced with the process of aligning an infrared lens on a test bench know how cumbersome and time consuming the process can be. Now, with the touch of a button, the unit electronically switches between Visible and Infrared sources, and introduces a high-visibility alignment crosshair. This AlignMode provides shorter lens set-up times and improved alignment and throughput efficiency.

Great care has been taken to maximize the lifetime of both infrared and visible sources. The source drive current is set and monitored by the on-board microprocessor and is ramped up and down at a pre-set rate to minimize thermal stresses that shorten lamp lifetime. All sources include a keyed connector and are pre-aligned at Optikos. This permits them to be replaced in the field without the need for factory realignment or service.

Instrument Configurations

The OG-1000 family is built around a common housing and touchscreen control interface. The baseline visible/SWIR models include a 16-position automated target wheel, shutter, and visible light source, while the infrared models feature an additional ceramic infrared source and may be configured with or without an integrated chopper wheel. A chopper is required in order to modulate the signal when performing a scanning measurement whereas IR video measurements do not require a modulated optical signal. Standard target configurations are offered for each model that cover most common test needs, and additional targets are offered as options (such as USAF-1951). All models feature positions for two manual filter drawers that hold standard 1-inch or 25mm diameter spectral targets, and an automated target wheel is also available.

A Multispectral Object Generator from the OG-1000 family is usually included in every MTF test bench delivered by Optikos and is controlled directly by the OpTest 7™ software. These target generators are also available for stand-alone purchase so that they may be used as general-purpose sources of structured light in various laboratory setups. In these cases, the operator may control them using the touchscreen interface, the HC-1000 handheld controller (requires PS-1300 series power supply), or by issuing commands over an RS232 or RS485 interface. In these instances, we encourage you to contact us so that one of our engineers can guide you in ordering the Object Generator that will best meet your needs.

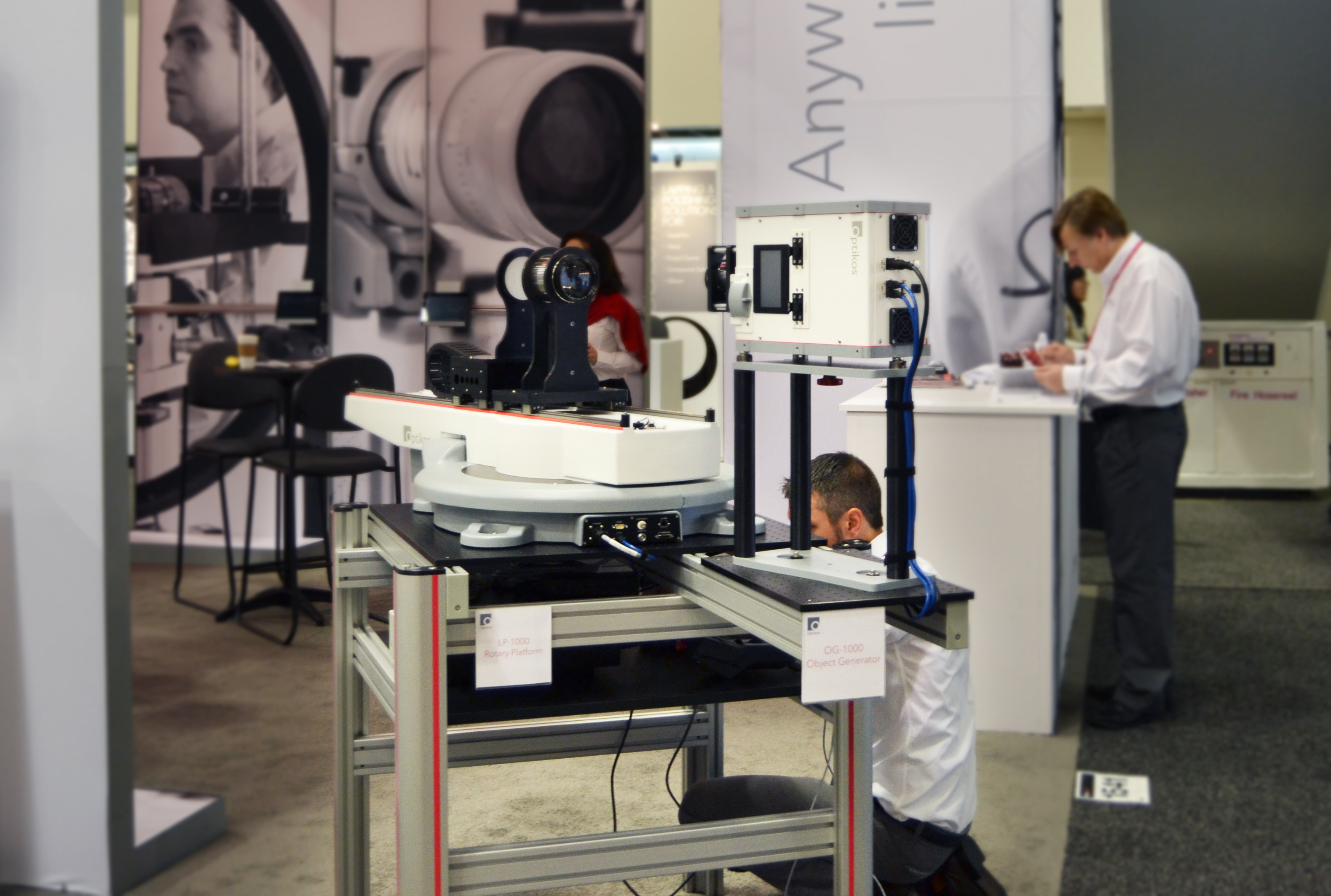

The OG 1000 multispectral object generator being set up with the LP 1000 lens platform for display at Photonics West.

OG-1000 Models

Features Common to all Models

- Every object generator includes a high-speed, 16-position target wheel with precision aligned and calibrated laser cut apertures (not all models have standard fully-populated target wheels).

- High-speed shutter for rapid sampling of background signal to improve accuracy and repeatability of MTF measurements on lenses that do not perform near the diffraction limit. The shutter closes between target changes to prevent detector saturation.

- Color touchscreen display provides intuitive user interface for local control.

- Single button “AlignMode”. A single touchscreen button switches from your test configurations (visible or infrared) to a visible alignment target, and then switches back to your test configuration.

- Two manual filter drawers in (1 inch diameter filters) in collimated space standard. Motorized filter wheel optional for all models.

- CANbus interface.

- RS-232 or RS-485 interface (factory set).

- Three-ball kinematic interface factory- mounted to face specified by user.

- Intelligent thermal control minimizes air turbulence by providing forced convection in response to internal temperature monitoring.

- Includes an external 18V universal input power supply.

OG-1110 Visible Object Generator for Video Systems

- 3200K Tungsten Halogen emitter.

- Visible light diffuser.

- Standard Target Set: Alignment Target + 6 pinholes (3μm, 10μm, 30μm, 100μm, 300μm, 1000μm).

OG-1210 Visible-SWIR Object Generator for Video Systems

- 3200K Tungsten Halogen emitter.

- Visible/SWIR light diffuser.

- Standard Target Set: Alignment Target + 6 pinholes (3μm, 10μm, 30μm, 100μm, 300μm, 1000μm).

OG-1220 Visible-SWIR Object Generator for Scanning Systems

- 3200K Tungsten Halogen emitter.

- Visible/SWIR light diffuser.

- Automated chopper wheel (0-2000Hz).

- Standard Target Set: Alignment Target + 6 pinholes (3μm, 10μm, 30μm, 100μm, 300μm, 1000μm) + 4 horizontal and vertical slit pairs (15μm, 50μm, 150μm, 500μm).

OG-1310 Visible-SWIR-IR Object Generator for Video Systems

- 3200K Tungsten Halogen emitter.

- 1000K Ceramic IR Emitter.

- Visible/SWIR light diffuser.

- Standard Target Set: Alignment Target + 6 pinholes (3μm, 10μm, 30μm, 100μm, 300μm, 1000μm) + 4 horizontal and vertical slit pairs (15μm, 50μm, 150μm, 500μm).

OG-1320 Visible-SWIR-IR Object Generator for Scanning Systems

- 3200K Tungsten Halogen emitter.

- 1000K Ceramic IR Emitter.

- Visible/SWIR light diffuser.

- Automated chopper wheel (0-2000Hz).

- Standard Target Set: Alignment Target + 6 pinholes (3μm, 10μm, 30μm, 100μm, 300μm, 1000μm) + 4 horizontal and vertical slit pairs (15μm, 50μm, 150μm, 500μm).