There is a Difference

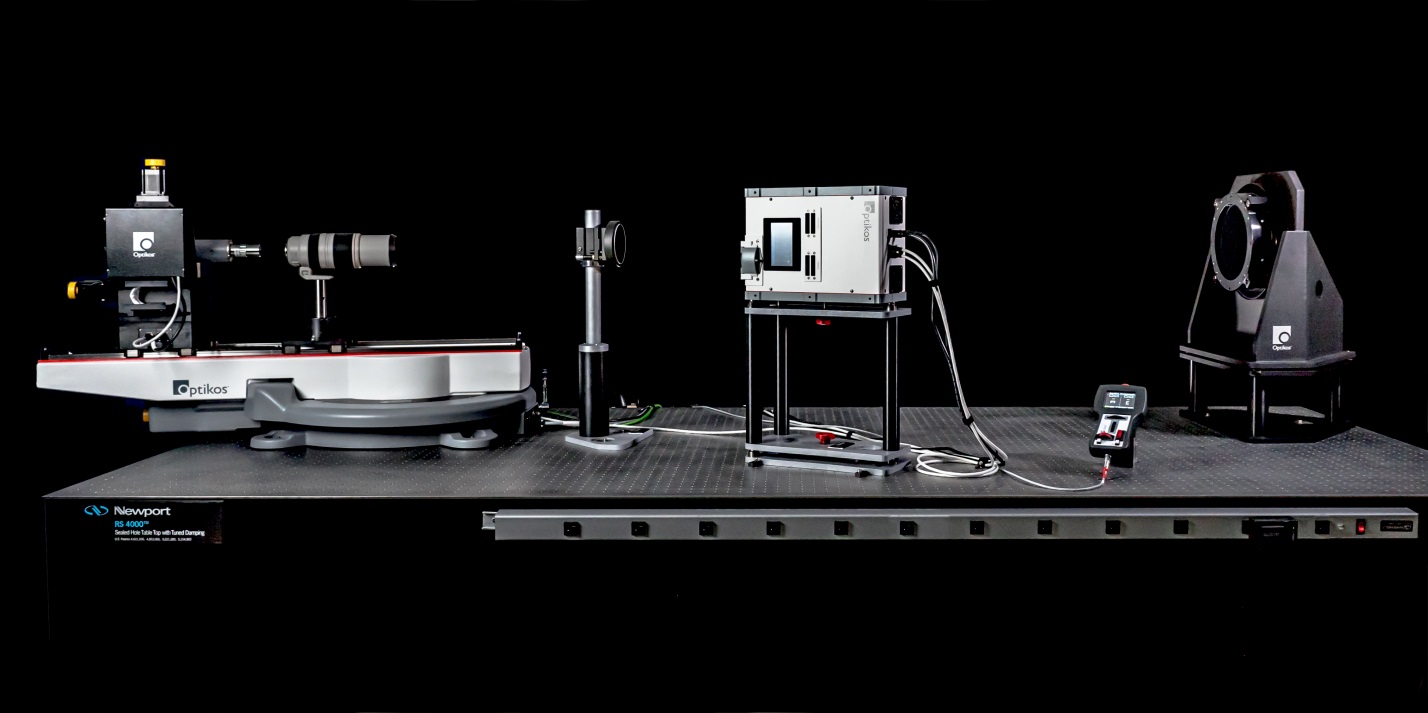

The OpTest Lens Measurement System has been completely redesigned by Optikos engineers to include the latest technologies and innovations in optical and opto-mechanical engineering. Other products on the market compromise by manufacturing their systems around general purpose off-the-shelf lab components, while every step of an Optikos solution is a custom one. OpTest systems are composed almost completely of custom optics, mechanics, and electronics designed by Optikos engineers solely for the purpose of lens testing.

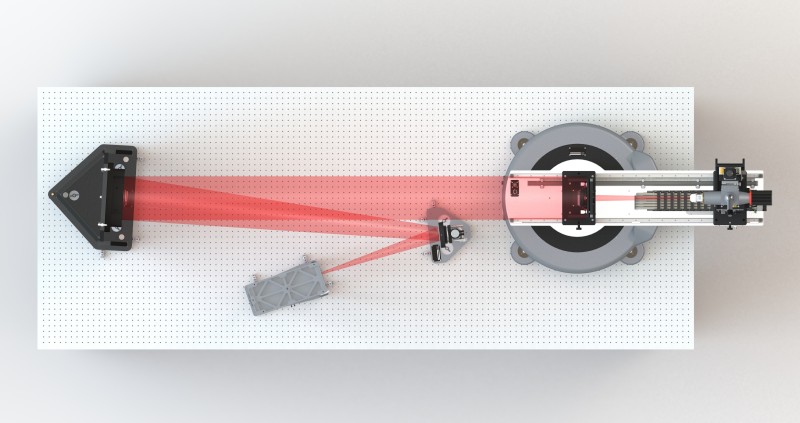

Figure 7 – An infinite conjugate OpTest® System.

The result is that our customers now have access to the most advanced metrology tool for performing accurate and time-efficient lens measurements.

Custom-Designed to Fit Your Needs

Your optical testing system should be built from sub-assemblies and components that meet your immediate needs, but also provide a simple upgrade path as your needs change. The Optikos approach provides you with a technical as well as economical solution: one that doesn’t become obsolete as your application or business develops – one that is flexible enough to meet your requirements now and in the future.

With the range of products available, selecting the components that best suit your purposes and give you maximum flexibility can be a challenge. In the optical testing section that follows, you will be introduced to a range of products that will work together to perform the tests that meet your unique application. Descriptions and illustrations explain how each product may used to create the overall system.

A Buildable Solution

The modular components of the OpTest system can be configured to test most types of lenses. Selecting and configuring modules appropriate for the optical system under test requires defining how the system is to be used, in particular:

- Location of object and image conjugates

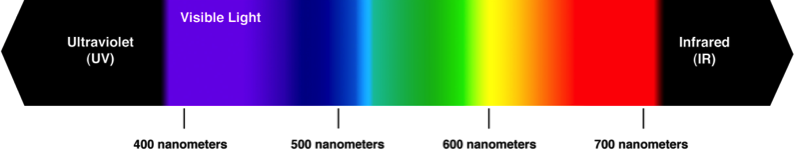

- Spectral range

- Spatial resolution

- Image and object size and system field-of-view

- Pupil diameters, F/number, and numerical aperture

- Physical dimension and system layout

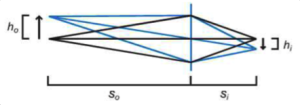

For location of object and image conjugates, most optical systems fall into three groups:

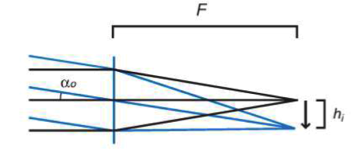

Infinite conjugate systems:

The object plane is located at infinity.

Examples: Camera lenses, eyepieces, infinity-correct microscope objectives

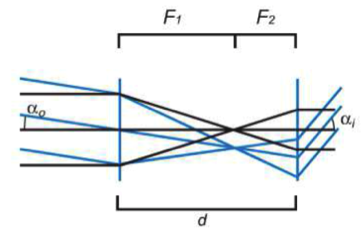

Afocal systems: Both the object and image plane are at infinity.

Examples: Telescopes, binoculars, and beam expanders

Finite conjugate systems:

Both the object and image planes are located at finite distances.

Examples: Photographic enlarging lenses, macro lenses, fiber optic faceplates, image tubes, and photolithography lenses

The OpTest System supports image analyzers that can operate over spectral wavelength from the UV to the LWIR.

All optical systems are limited in their ability to form images due to spatial resolution. One fundamental limitation stems from the wave nature of light. In a case where the wave nature of light limits the performance of an optical system, the system has “diffraction limited” resolution.

The performance of an optical system can also be limited by the design of the system or by manufacturing imperfections. In this case the optical system is resolution-limited by aberrations. The residual aberrations of the optical testing system must be small compared to those of the system under test. The resulting image analyzer of the test system must also have sufficient resolution to analyze the resulting image formed by the optical system under test. Spatial resolution is specified in line-pairs per millimeter for infinite and finite conjugate systems. It is specified in cycles per milliradian for afocal systems.

The test system must be able to cover the field-of-view (FOV) of the system under test in both object and image space. For infinite conjugate systems, the test system must cover the angular FOV in object space and linear dimension of the full field image height. For finite conjugate testing the translation stages must be able to cover the full object and image heights. For testing afocal systems, it is necessary to span the angular FOV in both object and image space.

The test system must be able to fill the entrance pupil of the system under test in object space and collect light form the entire exit pupil. For infinite conjugate and afocal systems under test, the entrance pupil diameter specifies the size of the collimated beam required in object space. Image space requirements are specified by the exit pupil diameter of afocal systems, whereas the working F/number or numerical aperture is relevant when testing infinite or finite conjugate systems.

The OpTest system needs an optical table to accommodate system components and a folded optical path. The optical system under test may be massive or may include folded optical paths or other unusual physical characteristics. An optical table with ¼”-20 on 1” centers or M6 on 25mm centers is required for OpTest™ systems.